Ford Fiesta: Manual Transmission - 6-Speed Manual Transmission – B6 / Output Shaft. Disassembly and Assembly of Subassemblies

Special Tool(s) / General Equipment

|

205-199

(T83T-3132-A1)

Installer, Spindle/Axle Shaft T83-4000-A TKIT-1983-F TKIT-1983-FLM TKIT-1983-FX |

|

205-D015

(D80L-630-4)

Step Plate |

|

211-014 Remover, Steering Wheel |

| Hydraulic Press | |

| Hot Air Gun | |

| Bearing Separator | |

| Vise | |

| Vise Jaw Protectors | |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Dual Clutch Transmission Fluid XT-11-QDC |

WSS-M2C200-D2 |

DISASSEMBLY

NOTE: If the front bearing needs to be replaced, replace the output shaft.

-

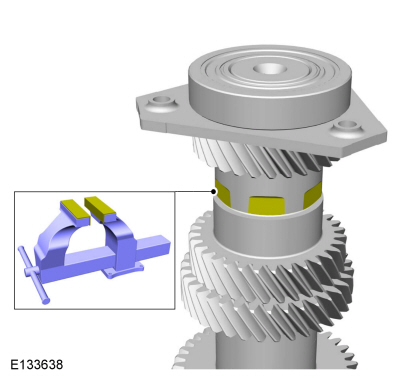

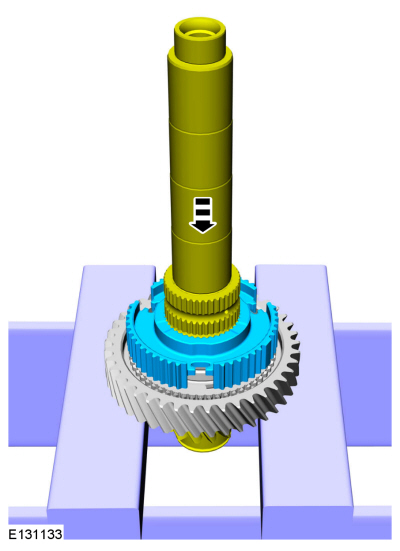

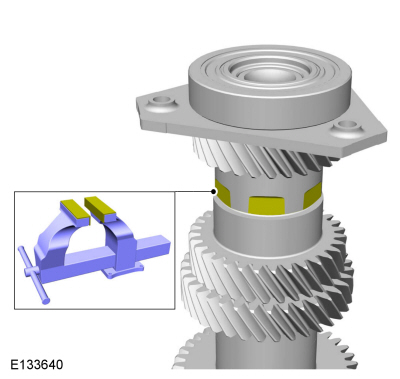

NOTICE: Use vise jaw protectors or damage to the output shaft can occur.

Install the output shaft in a vise. Clamp the output shaft on the flat surfaces.

Use the General Equipment: Vise

Use the General Equipment: Vise Jaw Protectors

|

-

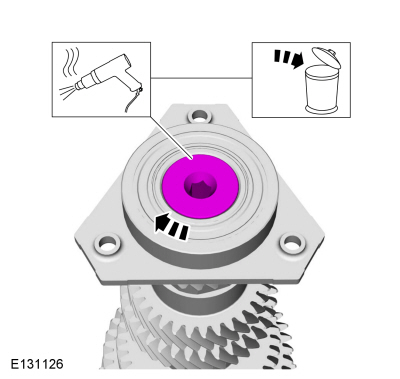

NOTE: The component has a left-hand thread.

Heat the bolt to melt the Loctite® and remove and discard the rear bearing bolt.

Use the General Equipment: Hot Air Gun

|

-

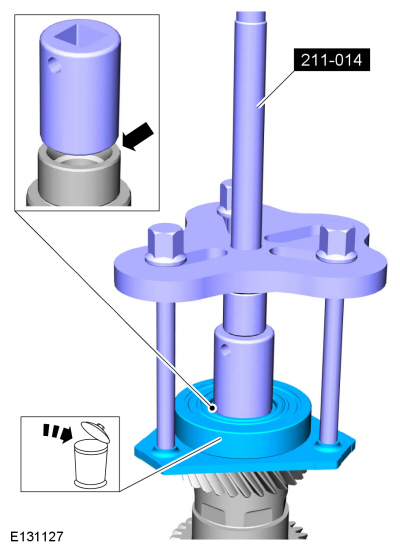

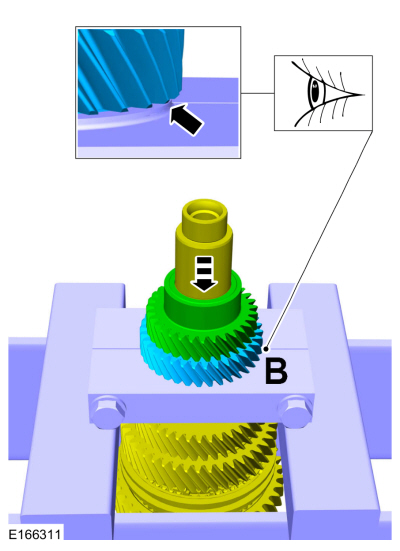

Using the special tools, remove the output shaft rear bearing.

Use Special Service Tool: 211-014 Remover, Steering Wheel.

|

-

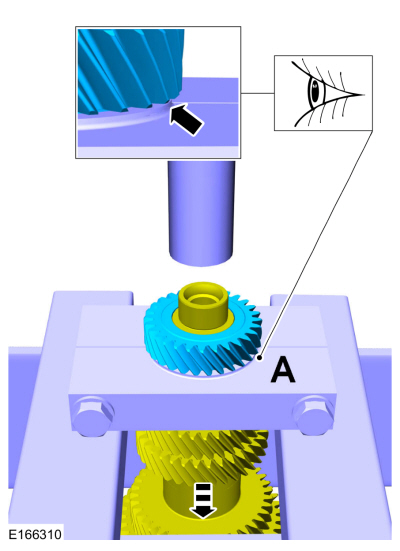

NOTE: Only tighten the bolts on the bearing separator finger tight.

Remove 6th gear.

Use Special Service Tool: 205-D015 (D80L-630-4) Step Plate.

Use the General Equipment: Hydraulic Press

Use the General Equipment: Bearing Separator

|

-

NOTE: Only tighten the bolts on the bearing separator finger tight.

Remove 5th and 4th gear.

Use the General Equipment: Bearing Separator

Use the General Equipment: Hydraulic Press

|

-

-

Push the 1st-2nd gear synchronizer sleeve down to the 1st gear position.

-

Remove 2nd and 3rd gear.

Use the General Equipment: Bearing Separator

Use the General Equipment: Hydraulic Press

-

Push the 1st-2nd gear synchronizer sleeve down to the 1st gear position.

|

-

Remove the 2nd gear synchronizer assembly.

|

-

NOTE: Note the position of the components before removal.

-

Remove the 1st-2nd gear synchronizer sleeve.

-

Remove the detents.

-

Remove the 1st-2nd gear synchronizer sleeve.

|

-

Remove the 1st-2nd gear synchronizer hub.

Use the General Equipment: Hydraulic Press

|

-

Remove 1st gear, release the roller bearing retainer and remove the roller bearing. Remove the thrust washer.

|

ASSEMBLY

-

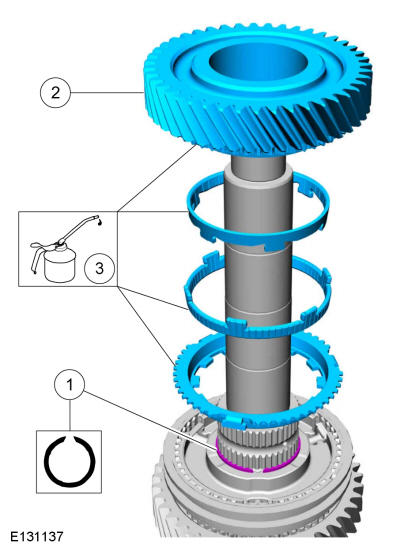

Install the thrust washer. Install the roller bearing and connect the roller bearing cage. Install 1st gear.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

|

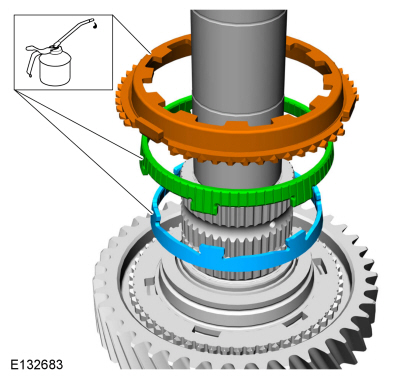

-

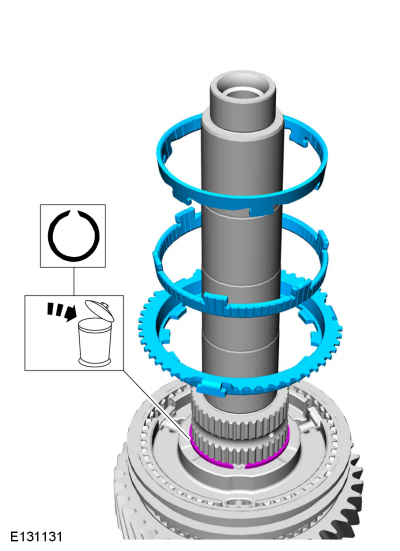

Lubricate the 1st gear synchronizer in transmission fluid and install the synchronizer.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

|

-

Using the special tools, install the 1st-2nd gear

synchronizer hub. Align the hub with the 1st gear synchronizer.

Use Special Service Tool: 205-D015 (D80L-630-4) Step Plate.

Use the General Equipment: Hydraulic Press

|

-

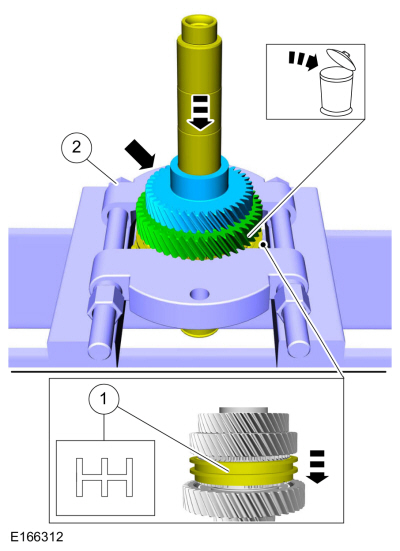

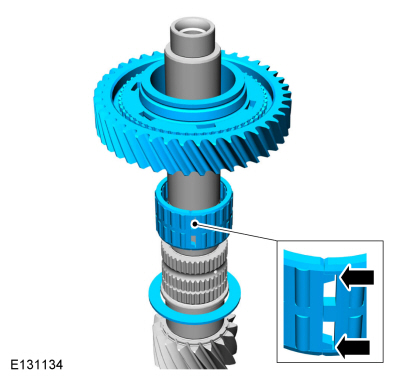

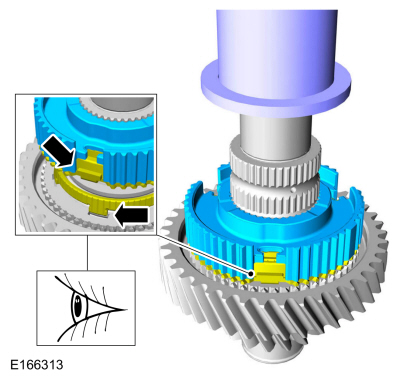

NOTE: Make sure that the components are installed to the position noted before removal.

-

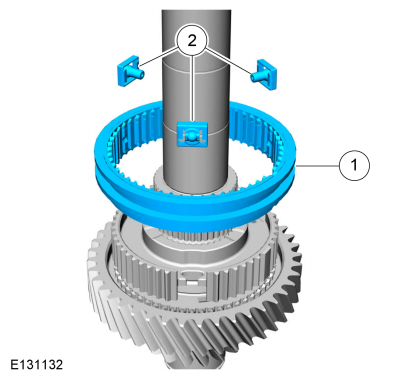

Install the 1st-2nd gear synchronizer sleeve.

-

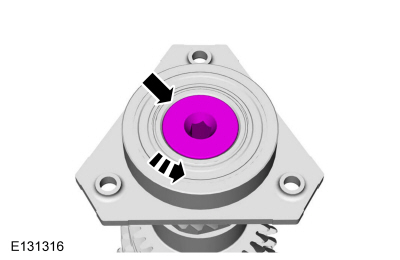

Lubricate the 1st-2nd gear synchronizer sleeve

detents in transmission fluid and install them so they fit in the

1st-2nd gear synchronizer hub as shown.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

-

Install the 1st-2nd gear synchronizer sleeve.

|

-

-

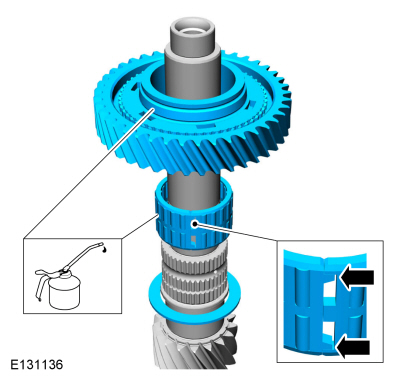

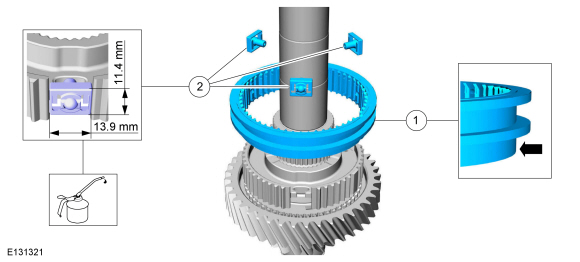

Install the 1st-2nd gear synchronizer hub snap ring.

-

Lubricate the parts in transmission fluid and install the 2nd gear synchronizer assembly.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

-

Install 2nd gear.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

-

Install the 1st-2nd gear synchronizer hub snap ring.

|

-

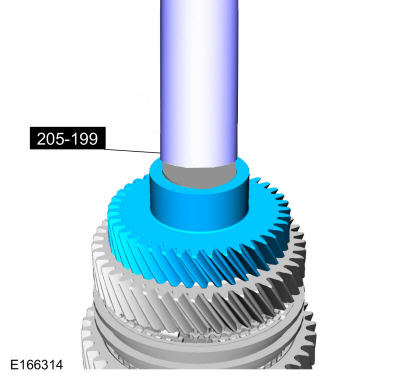

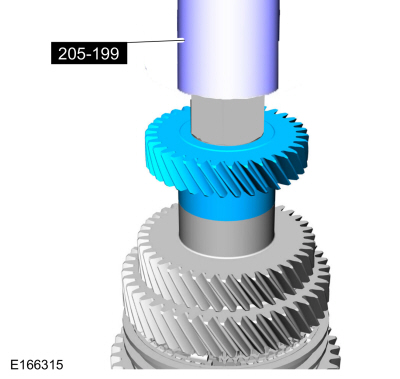

Using the special tools, install 3rd gear.

Use Special Service Tool: 205-199 (T83T-3132-A1) Installer, Spindle/Axle Shaft.

Use the General Equipment: Hydraulic Press

|

-

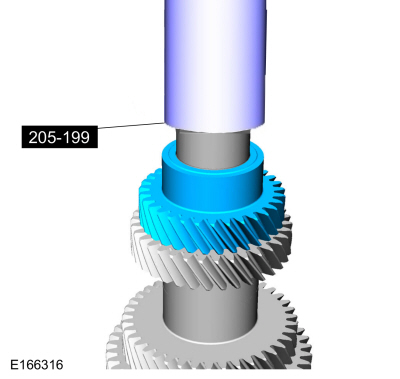

Using the special tools, install 4th gear.

Use Special Service Tool: 205-199 (T83T-3132-A1) Installer, Spindle/Axle Shaft.

Use the General Equipment: Hydraulic Press

|

-

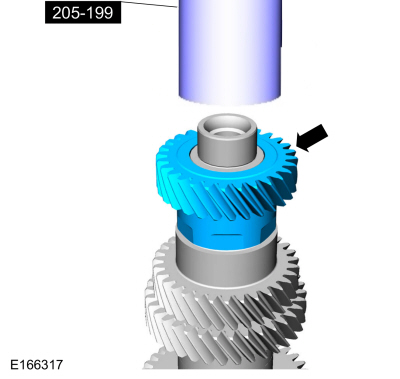

Using the special tools, install 5th gear.

Use Special Service Tool: 205-199 (T83T-3132-A1) Installer, Spindle/Axle Shaft.

Use the General Equipment: Hydraulic Press

|

-

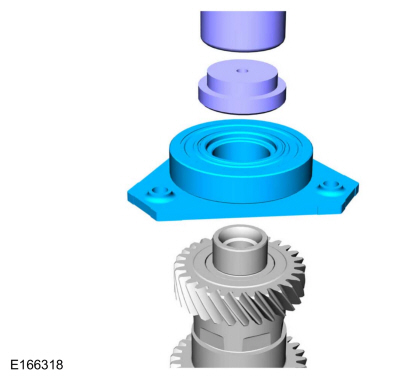

Using the special tools, install 6th gear.

Use Special Service Tool: 205-199 (T83T-3132-A1) Installer, Spindle/Axle Shaft.

Use the General Equipment: Hydraulic Press

|

-

Using the special tool, install the rear bearing.

Use Special Service Tool: 205-D015 (D80L-630-4) Step Plate.

Use the General Equipment: Hydraulic Press

|

-

NOTICE: Use vise jaw protectors.

Install the output shaft in a vise. Clamp the output shaft on the flat surfaces.

Use the General Equipment: Vise

Use the General Equipment: Vise Jaw Protectors

|

-

NOTE: The component has a left-hand thread.

Install a new rear bearing bolt.

Torque: 81 lb.ft (110 Nm)

|

Reverse Gear Output Shaft. Disassembly and Assembly of Subassemblies

Reverse Gear Output Shaft. Disassembly and Assembly of Subassemblies

Special Tool(s) /

General Equipment

205-D015

(D80L-630-4)

Step Plate

205-D016

(D80L-630-5)

Step Plate

307-679Installer, Countershaft Needle BearingTKIT-2010D-FLMTKIT-2010D-ROW

308-416Remover/Installer, Thrust Washer Bearing CupTKIT-1999A-F/LTTKIT-1999A-FM/FLM

Hydraulic Press

Puller

Bearing Separator

Materials

..

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Refrigerant System Tests - 1.6L EcoBoost (132kW/180PS) – Sigma. General Procedures

Inspection NOTE: Procedure 1 — Ambient Temperature between 21°C (70°F) and 38°C (100°F) NOTE: Variable compressors may not stroke up unless the ambient temperatures are above 21°C (70°F) when conducting the pressure mapping procedure. Variable compressor need to see a thermal load on the system in order to create normal operating pressures. Run the engi..

Ford Fiesta 2014 - 2019 Service Manual: Rear Door Window Regulator. Removal and Installation

Removal NOTE: RH shown, LH similar. NOTE: Removal steps in this procedure may contain installation details. All vehicles Remove the rear door trim panel. Refer to: Rear Door Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation). Remove the adhesive tape covers. Vehicles with man..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Fuel Pump. Removal and Installation

- Clutch - 6-Speed Manual Transmission – B6

- Maintenance Schedules

- Timing Belt. Removal and Installation

- Valve Clearance Adjustment. General Procedures

Brake Master Cylinder. Removal and Installation

Removal

NOTICE: If the fluid is spilled on the paintwork, the affected area must be immediately washed down with cold water.

NOTE: Removal steps in this procedure may contain installation details.

All vehicles

Remove the battery tray.Refer to: Battery Tray - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma (414-01 Battery, Mounting and Cables, Removal and Installation).

Refer to: Battery Tray - 1.6L EcoBoost (132kW/180PS) – Sigma (414-01 Battery, Mounting and Cables, Removal and Installation).

Disconnect the vacuum tube from the brake booster and detach the routing clip.