Ford Fiesta: Manual Transmission - 6-Speed Manual Transmission – B6 / Input Shaft. Disassembly and Assembly of Subassemblies

Ford Fiesta 2014 - 2019 Service Manual / Manual Transmission, Clutch, Transfer Case and Power Transfer Unit / Manual Transmission - 6-Speed Manual Transmission – B6 / Input Shaft. Disassembly and Assembly of Subassemblies

Special Tool(s) / General Equipment

|

205-199

(T83T-3132-A1)

Installer, Spindle/Axle Shaft T83-4000-A TKIT-1983-F TKIT-1983-FLM TKIT-1983-FX |

|

205-D015

(D80L-630-4)

Step Plate |

|

211-014 Remover, Steering Wheel |

|

307-679 Installer, Countershaft Needle Bearing TKIT-2010D-FLM TKIT-2010D-ROW |

| Hydraulic Press | |

| Hot Air Gun | |

| Bearing Separator | |

| Vise | |

| Vise Jaw Protectors | |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Dual Clutch Transmission Fluid XT-11-QDC |

WSS-M2C200-D2 |

DISASSEMBLY

-

-

Remove and discard the snap ring.

-

Using the special tools, remove and discard the front bearing.

Use the General Equipment: Hydraulic Press

Use the General Equipment: Bearing Separator

-

Remove and discard the snap ring.

|

-

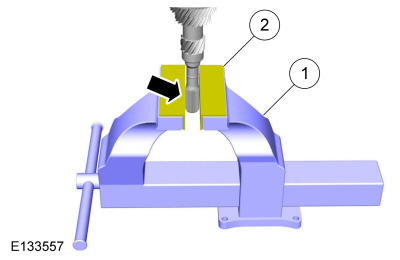

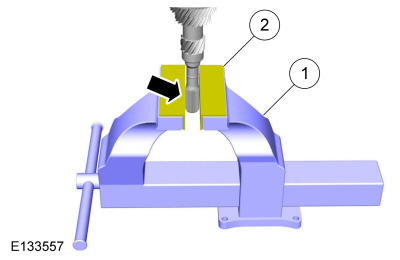

NOTICE: Use vise jaw protectors or damage to the splines can occur.

-

Install the input shaft in a vice.

Use the General Equipment: Vise

-

Use vice jaw protectors.

Use the General Equipment: Vise Jaw Protectors

-

Install the input shaft in a vice.

|

-

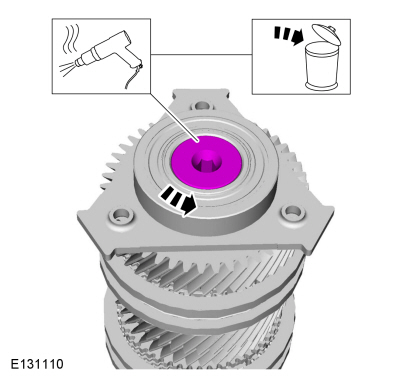

Heat the bolt to melt the Loctite® and remove and discard the rear bearing bolt.

Use the General Equipment: Hot Air Gun

|

-

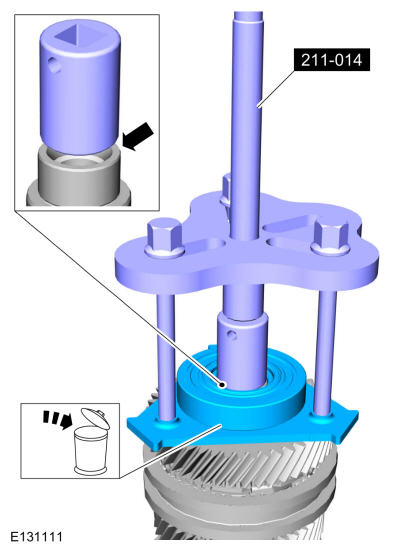

Using the special tools, remove and discard the rear bearing.

Use Special Service Tool: 211-014 Remover, Steering Wheel.

|

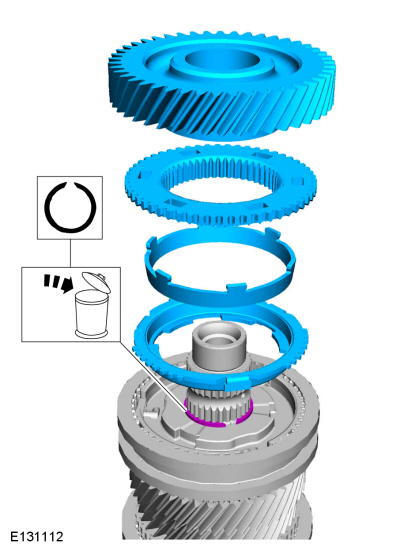

-

Remove 6th gear, 6th gear synchronizer assembly and

remove and discard the 5th-6th gear synchronizer hub snap ring.

|

-

Remove the 5th-6th gear synchronizer sleeve and the 3 detents.

|

-

Using the special tools, remove the 5th-6th gear synchronizer hub, 5th gear synchronizer assembly and 5th gear.

Use the General Equipment: Bearing Separator

Use the General Equipment: Hydraulic Press

|

-

NOTE: Note the position of the components before removal.

Remove the 4th gear retainer, 4th gear and the 4th gear synchronizer assembly. Remove and discard the 3rd-4th gear synchronizer hub snap ring.

|

-

Remove the 3rd-4th gear synchronizer sleeve and the detents.

|

-

Using the special tools, remove the 3rd-4th gear synchronizer hub, 3rd gear synchronizer assembly, and 3rd gear.

Use the General Equipment: Bearing Separator

Use the General Equipment: Hydraulic Press

|

-

Remove the 3rd gear bearing.

|

ASSEMBLY

-

NOTICE: Use vise jaw protectors or damage to the splines can occur.

-

Install the input shaft in a vice.

Use the General Equipment: Vise

-

Use vice jaw protectors.

Use the General Equipment: Vise Jaw Protectors

-

Install the input shaft in a vice.

|

-

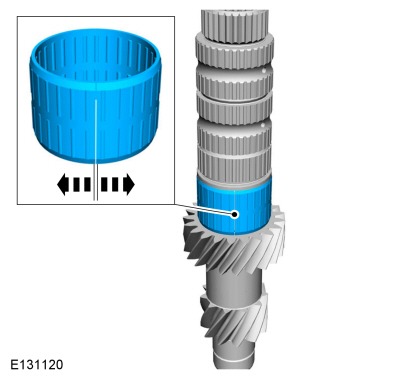

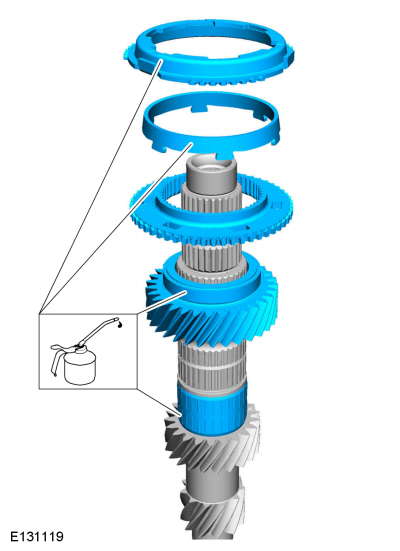

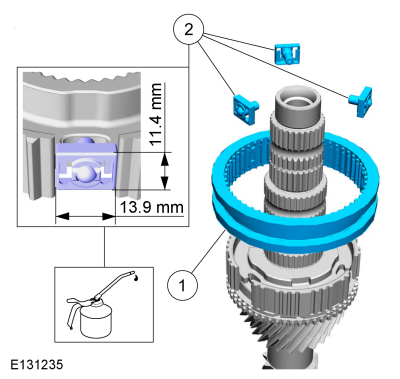

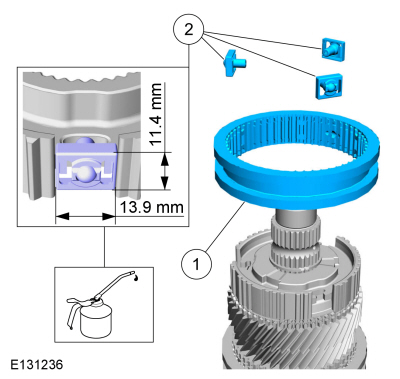

Lubricate the parts in transmission fluid and install

the 3rd gear bearing, 3rd gear and 3rd gear synchronizer assembly.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

|

-

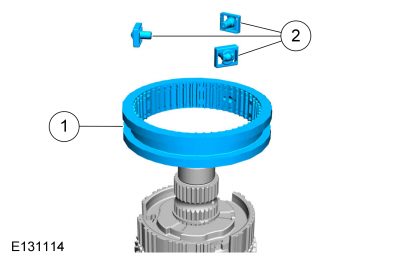

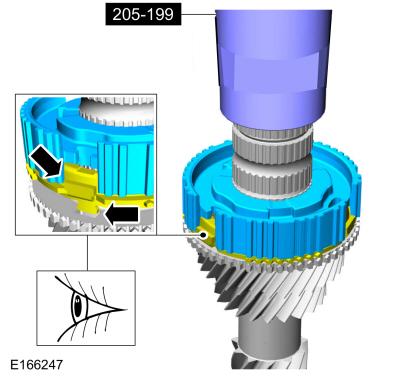

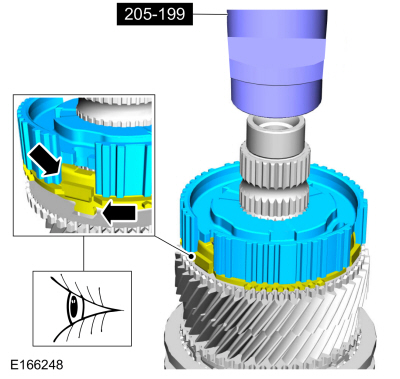

Using the special tools, install the 3rd-4th gear synchronizer hub.

Use Special Service Tool: 205-199 (T83T-3132-A1) Installer, Spindle/Axle Shaft.

|

-

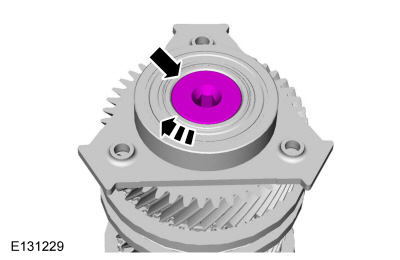

-

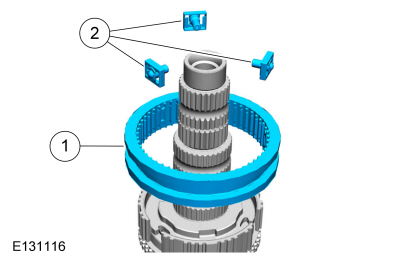

Install the 3rd-4th gear synchronizer sleeve.

-

Lubricate the 3rd-4th gear synchronizer sleeve

detents in transmission fluid and install them so they fit in the

3rd-4th gear synchronizer hub as shown.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

-

Install the 3rd-4th gear synchronizer sleeve.

|

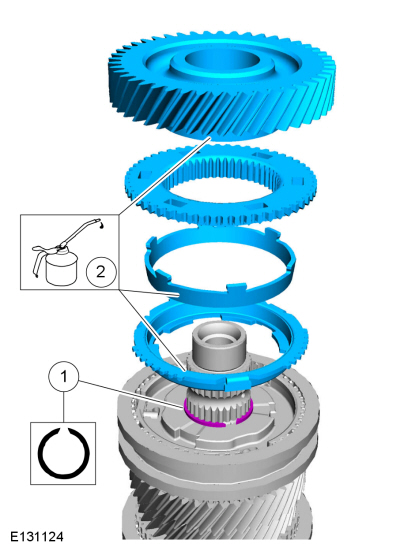

-

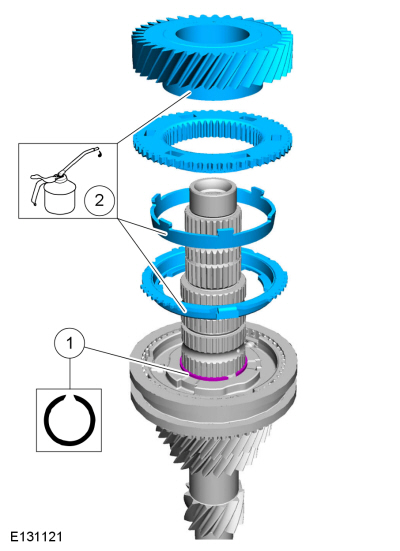

-

Install the 3rd-4th gear synchronizer hub snap ring.

-

Lubricate the parts in transmission fluid and

install the 4th gear synchronizer assembly and install 4th gear.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

-

Install the 3rd-4th gear synchronizer hub snap ring.

|

-

-

NOTE: Make sure that the components are installed to the position noted during removal.

Install the 4th gear retainer.

-

Lubricate the parts in transmission fluid and install 5th gear and the 5th gear synchronizer assembly.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

-

|

-

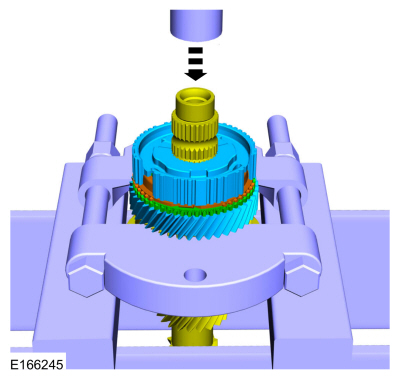

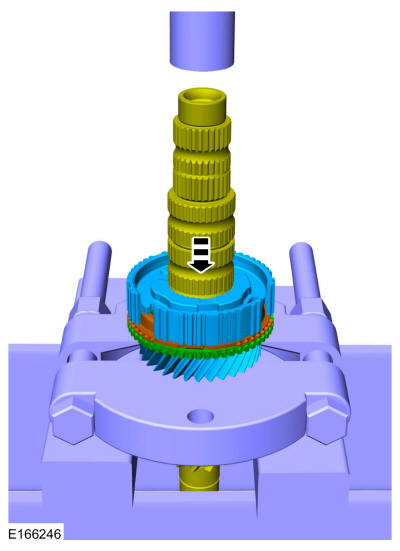

Using the special tools, install the 5th-6th gear synchronizer hub.

Use Special Service Tool: 205-199 (T83T-3132-A1) Installer, Spindle/Axle Shaft.

Use the General Equipment: Hydraulic Press

|

-

-

Install the 5th-6th gear synchronizer sleeve.

-

Lubricate the 5th-6th gear synchronizer sleeve

detents in transmission fluid and install them so they fit in the

5th-6th gear synchronizer hub as shown.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

-

Install the 5th-6th gear synchronizer sleeve.

|

-

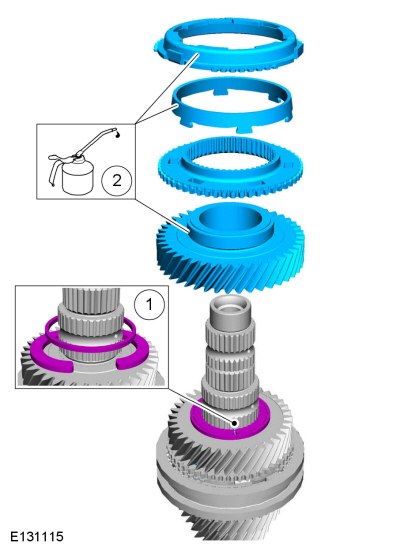

-

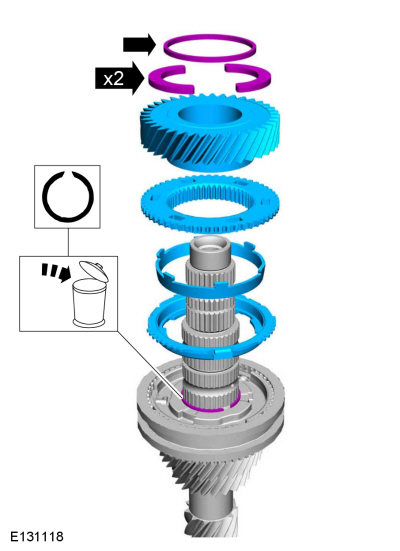

Install a new 5th-6th gear synchronizer hub snap ring.

-

Lubricate the parts in transmission fluid and

install the 6th gear synchronizer assembly and install 6th gear.

Material: Motorcraft® Dual Clutch Transmission Fluid / XT-11-QDC (WSS-M2C200-D2)

-

Install a new 5th-6th gear synchronizer hub snap ring.

|

-

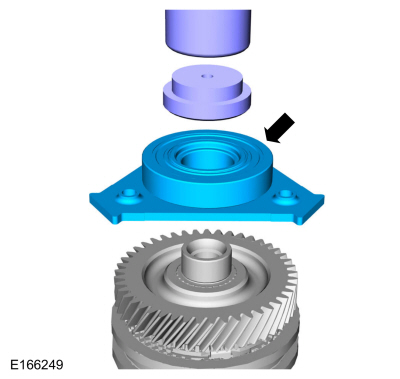

Using the special tools, install the rear bearing.

Use Special Service Tool: 205-D015 (D80L-630-4) Step Plate.

Use the General Equipment: Hydraulic Press

|

-

Install a new rear bearing bolt.

Torque: 81 lb.ft (110 Nm)

|

-

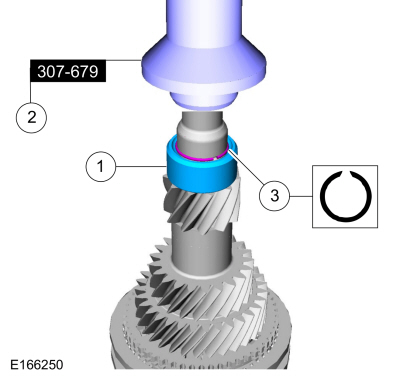

-

Position the front bearing on the input shaft.

-

Using the special tools, install the front bearing.

Use Special Service Tool: 307-679 Installer, Countershaft Needle Bearing.

Use the General Equipment: Hydraulic Press

-

Install a new snap ring.

-

Position the front bearing on the input shaft.

|

Differential. Disassembly and Assembly of Subassemblies

Differential. Disassembly and Assembly of Subassemblies

Special Tool(s) /

General Equipment

205-062Installer, Differential Bearing

Puller

Bearing Separator

Materials

Name

Specification

Motorcraft® Dual Clutch Transmission FluidXT-11-QDC

WSS-M2C200-D2

DISASSEMBLY

NOTICE:

Use vise jaw protectors...

Output Shaft. Disassembly and Assembly of Subassemblies

Output Shaft. Disassembly and Assembly of Subassemblies

Special Tool(s) /

General Equipment

205-199

(T83T-3132-A1)

Installer, Spindle/Axle ShaftT83-4000-ATKIT-1983-FTKIT-1983-FLMTKIT-1983-FX

205-D015

(D80L-630-4)

Step Plate

211-014Remover, Steering Wheel

Hydraulic Press

Hot Air Gun

Bearing Separator

Vise

Vise Jaw Protectors

Materials

Name

Specification

..

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Rear Door Speaker. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the rear door trim panel. Refer to: Rear Door Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation). Remove the bolts and the rear door speaker. Disconnect the electrical connector. Torque: 18 lb.in (2 Nm) ..

Ford Fiesta 2014 - 2019 Service Manual: Rear Door Window Control Switch. Removal and Installation

Removal NOTE: LH side shown, RH side similar. Remove the rear door window control switch. Remove the rear door window control switch from the door trim panel. Disconnect the rear door window control switch electrical connector. Installation To install, reverse the removal procedure. ..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Engine - 1.6L EcoBoost (132kW/180PS) – Sigma

- Engine System - General Information

- Service Information

- Maintenance Schedules

- Engine Component View. Description and Operation

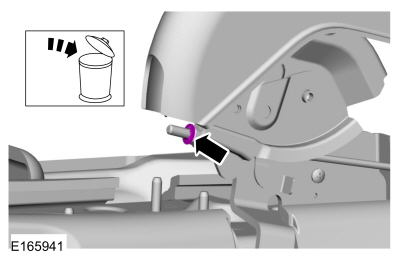

Parking Brake Control. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

Remove the floor console.Refer to: Floor Console (501-12 Instrument Panel and Console, Removal and Installation).

Remove the driver seat.

Refer to: Front Seat (501-10 Seating, Removal and Installation).

Remove the parking brake cable adjustment lock nut.

Loosen the parking brake cable adjustment nut.

Loosen the parking brake cable adjustment nut.

Copyright © 2026 www.fofiesta7.com