Ford Fiesta: Side Panel Sheet Metal Repairs / Rocker Panel - 4-Door. Removal and Installation

Ford Fiesta 2014 - 2019 Service Manual / Body and Paint / Side Panel Sheet Metal Repairs / Rocker Panel - 4-Door. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Hot Air Gun | |

| Air Body Saw | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers | |

| Folding Rule |

Materials

| Name | Specification |

|---|---|

| Metal Bonding Adhesive TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

- |

Removal

-

Refer to: Body Repair Health and Safety and General Precautions (100-00 General Information, Description and Operation). WARNING:

Before beginning any service procedure in this

manual, refer to health and safety warnings in section 100-00 General

Information. Failure to follow this instruction may result in serious

personal injury.

WARNING:

Before beginning any service procedure in this

manual, refer to health and safety warnings in section 100-00 General

Information. Failure to follow this instruction may result in serious

personal injury.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering and Repowering (501-20B Supplemental Restraint System, General Procedures).

-

Remove the following items:

Refer to: Fender (501-02 Front End Body Panels, Removal and Installation).

Refer to: Rocker Panel Moulding (501-08 Exterior Trim and Ornamentation, Removal and Installation).

Refer to: Front Door (501-03 Body Closures, Removal and Installation).

Refer to: Rear Door (501-03 Body Closures, Removal and Installation).

Refer to: A-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: B-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: C-Pillar Lower Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Front Seat (501-10 Seating, Removal and Installation).

Refer to: Rear Seat Cushion (501-10 Seating, Removal and Installation).

Refer to: Rear Seat Backrest (501-10 Seating, Removal and Installation).

-

Remove the hood.

-

Remove the lower door hinges.

-

Remove the rear wheel arch trim.

-

Position the carpeting and wiring harness away from the working area.

-

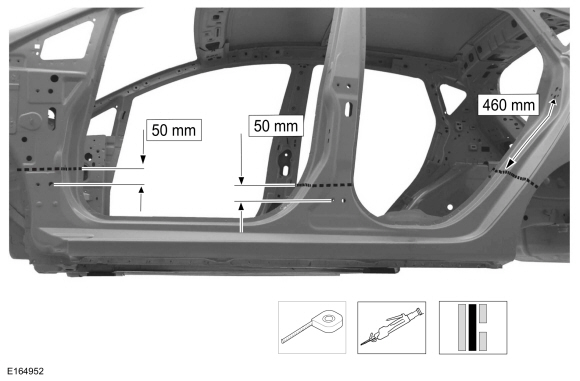

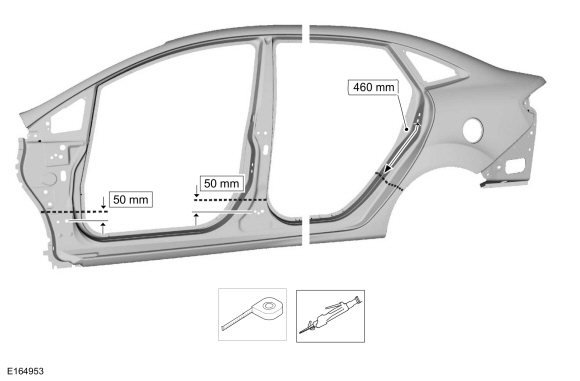

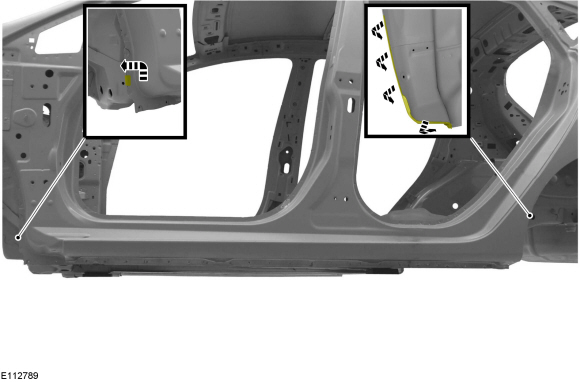

Carefully measure and cut the outer panel only of the body side panel.

Use the General Equipment: Folding Rule

Use the General Equipment: Air Body Saw

|

-

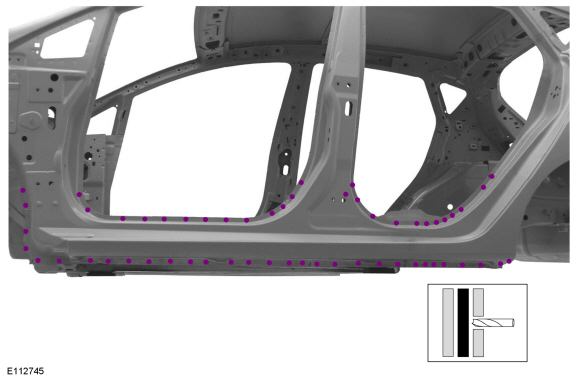

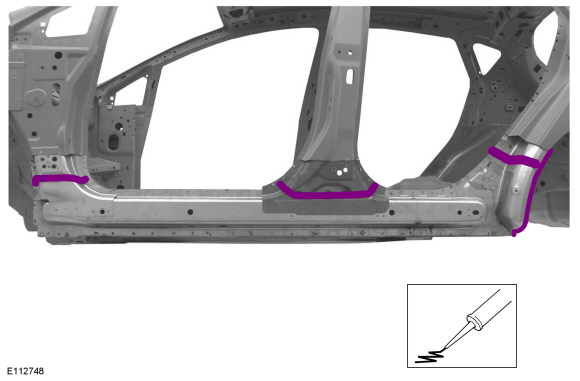

Drill out the spot welds from rocker panel.

Use the General Equipment: Spot Weld Drill Bit

|

-

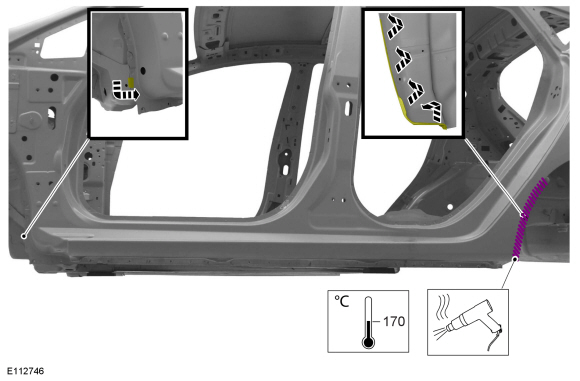

Break the adhesive bond and position aside the wheel arch.

Use the General Equipment: Hot Air Gun

|

-

Break the adhesive bond and remove the outer rocker panel section.

Use the General Equipment: Hot Air Gun

|

Installation

-

Carefully measure and cut the replacement panels to fit repair area.

Use the General Equipment: Folding Rule

Use the General Equipment: Air Body Saw

|

-

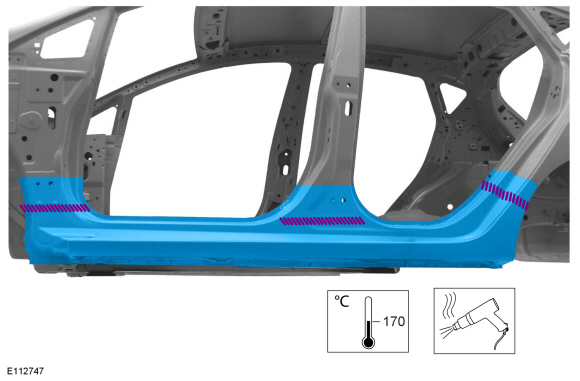

Apply adhesive as indicated.

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

|

-

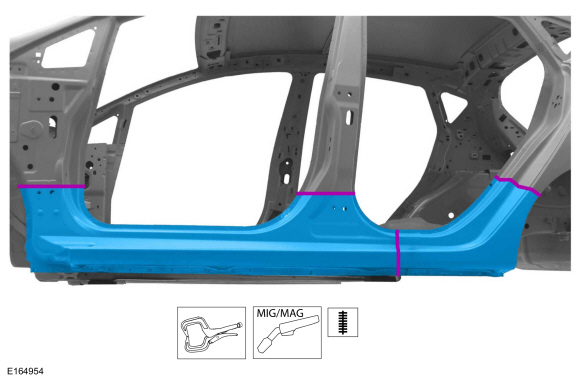

Install, clamp and seam weld the replacement rocker panel sections.

Use the General Equipment: Locking Pliers

Use the General Equipment: MIG/MAG Welding Equipment

|

-

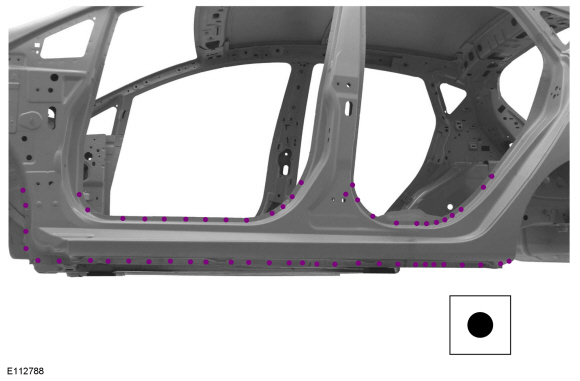

Spot weld the replacement rocker panel.

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Reposition the wheel arch.

|

-

Metal finish the repair area using typical metal finishing techniques.

-

Sealing work: All areas must be sealed to production level.

-

Refinish using an approved Ford paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reposition the wiring harness and carpet to the original position.

-

Install the rear wheel arch trim.

-

Install the lower door hinges.

-

Install the hood.

-

Install the following items:

Refer to: C-Pillar Lower Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: B-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: A-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Rear Seat Backrest (501-10 Seating, Removal and Installation).

Refer to: Rear Seat Cushion (501-10 Seating, Removal and Installation).

Refer to: Front Seat (501-10 Seating, Removal and Installation).

Refer to: Rocker Panel Moulding (501-08 Exterior Trim and Ornamentation, Removal and Installation).

Refer to: Fender (501-02 Front End Body Panels, Removal and Installation).

Refer to: Rear Door (501-03 Body Closures, Removal and Installation).

Refer to: Front Door (501-03 Body Closures, Removal and Installation).

-

Align the following items:

Refer to: Front Door Alignment (501-03 Body Closures, General Procedures).

Refer to: Rear Door Alignment (501-03 Body Closures, General Procedures).

Refer to: Hood Alignment (501-03 Body Closures, General Procedures).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering and Repowering (501-20B Supplemental Restraint System, General Procedures).

Rocker Panel - 5-Door. Removal and Installation

Rocker Panel - 5-Door. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Hot Air Gun

Air Body Saw

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Folding Rule

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Removal

..

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Engine Cooling - System Operation and Component Description. Description and Operation

System Operation Engine coolant flows primarily from the engine to the radiator circuit and back to the coolant pump. Coolant is sent from the coolant pump through the engine block and cylinder heads. A separate circuit from the engine also feeds the heater core and turbochargers with coolant. The coolant pump, operated by engine rotation through the accessory drive belt, circ..

Ford Fiesta 2014 - 2019 Service Manual: Rear View Mirrors - Overview. Description and Operation

Overview - Exterior, Power The power mirrors allow the LH and RH exterior mirror glass position to be adjusted electronically by the driver. The exterior mirror glass position is controlled by the exterior mirror control switch. Selecting the LH or RH position of the exterior mirror selection switch determines which power mirror glass to control. Overview - Exterior, Heated Th..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Front Strut and Spring Assembly. Removal and Installation

- Front Subframe. Removal and Installation

- Maintenance Schedules

- Service Information

- Engine - 1.6L EcoBoost (132kW/180PS) – Sigma

Component Bleeding. General Procedures

Special Tool(s) / General Equipment

Master Cylinder Bleeding SetBleeding

NOTICE: If the fluid is spilled on the paintwork, the affected area must be immediately washed down with cold water.

Master Cylinder

NOTE: When a new brake master cylinder has been installed, it should be primed to prevent air from entering the system.

NOTE: Make sure the area around the master cylinder cap is clean and free of foreign material.

Remove the brake fluid reservoir cap.Copyright © 2026 www.fofiesta7.com