Ford Fiesta: Engine System - General Information / Powertrain/Drivetrain Mount Neutralizing. General Procedures

Adjustment

-

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

Remove the battery tray.

Refer to: Battery Tray - 1.6L EcoBoost (132kW/180PS) – Sigma (414-01 Battery, Mounting and Cables, Removal and Installation).

Refer to: Battery Tray - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma

(414-01 Battery, Mounting and Cables, Removal and Installation).

-

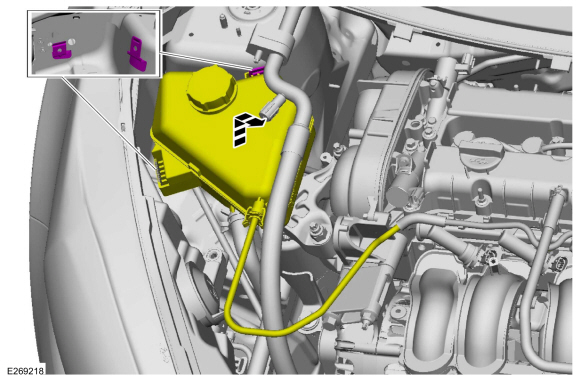

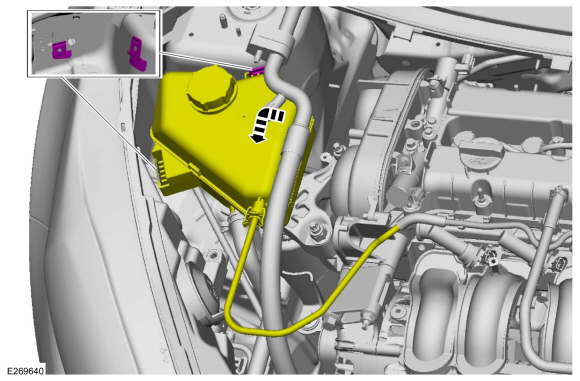

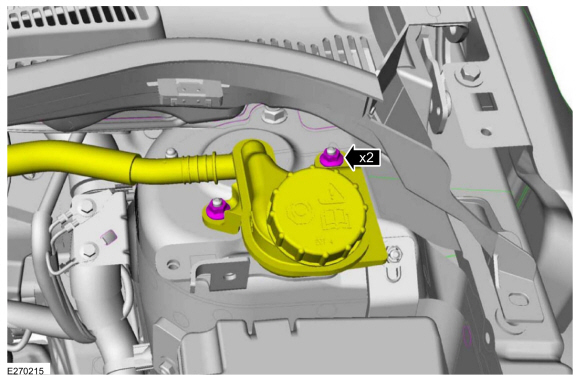

Position the degas bottle aside.

-

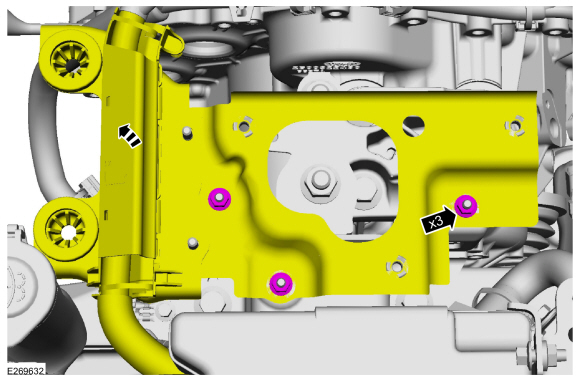

Loosen, but do not remove the engine mount bolts.

-

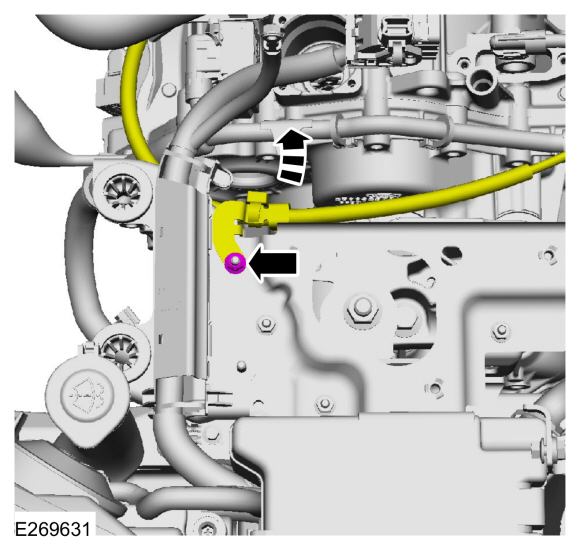

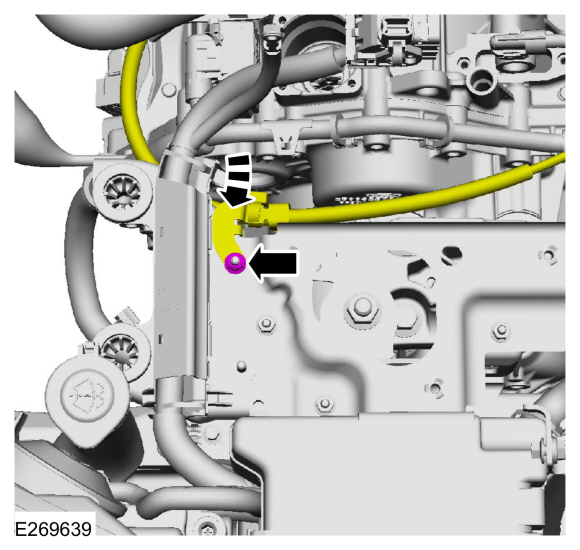

Remove the nut and position the wire aside.

-

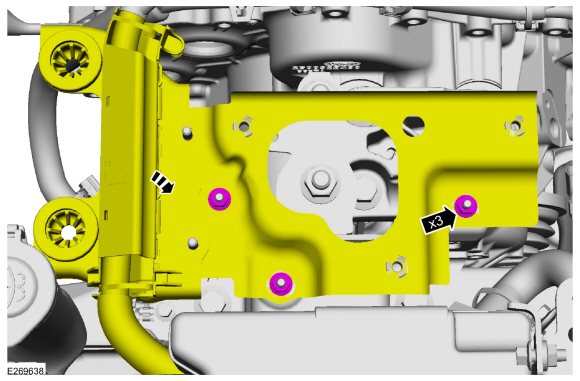

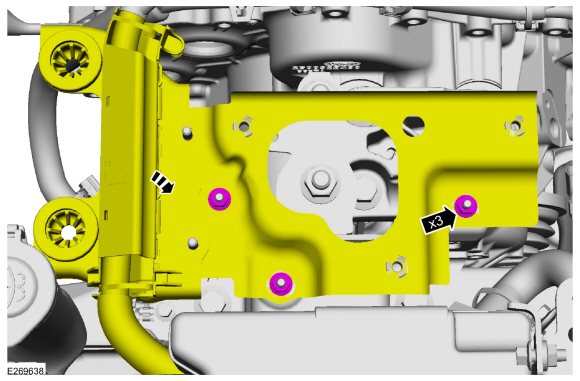

Remove the nuts and position the battery tray bracket aside.

-

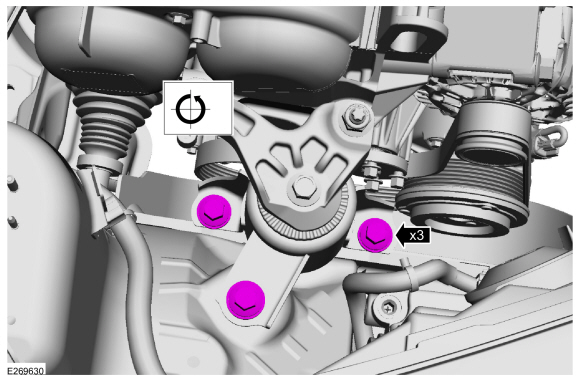

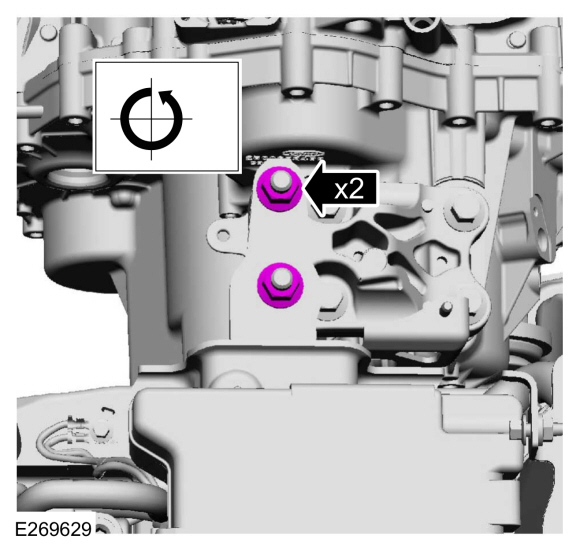

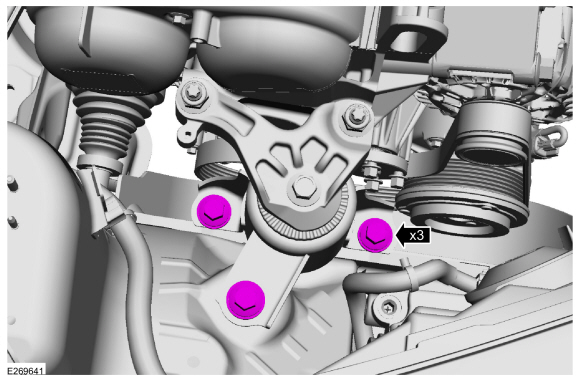

Loosen, but do not remove the transmission mounting assembly nuts.

-

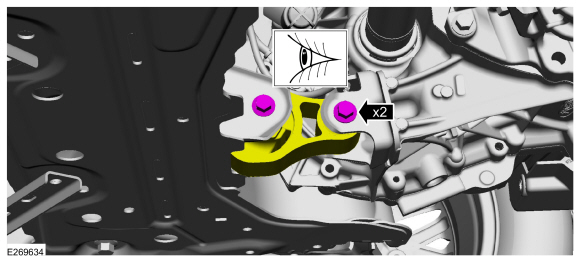

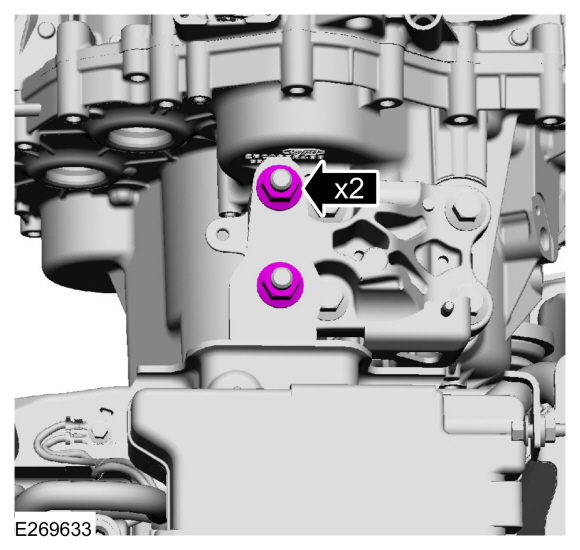

Loosen, but do not remove the 2 roll restrictor bolts. Verify that the roll restrictor is loose.

-

Install the battery tray bracket and nuts.

Torque:

18 lb.ft (25 Nm)

-

Install the battery tray.

Refer to: Battery Tray - 1.6L EcoBoost (132kW/180PS) – Sigma (414-01 Battery, Mounting and Cables, Removal and Installation).

Refer to: Battery Tray - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma

(414-01 Battery, Mounting and Cables, Removal and Installation).

-

Install the battery.

Refer to: Battery (414-01 Battery, Mounting and Cables, Removal and Installation).

-

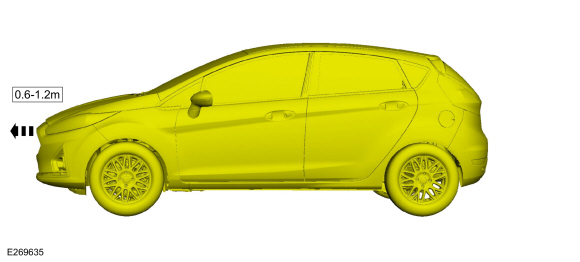

NOTE:

Do not twist or strain the powertrain/drivetrain mounts or damage to the mounts may occur.

Start the vehicle and move it forward 0.6 m (1.97 ft) - 1.2 m (3.94 ft).

-

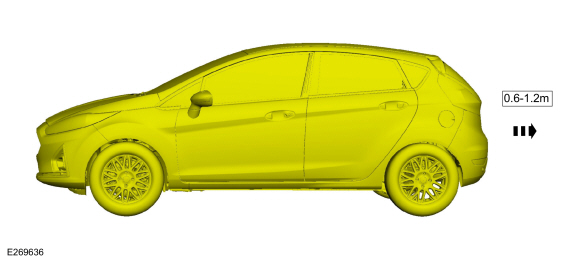

NOTE:

Do not twist or strain the powertrain/drivetrain mounts or damage to the mounts may occur.

Move the vehicle in reverse the same distance 0.6 m (1.97 ft) - 1.2 m (3.94 ft).

-

Remove the battery tray.

Refer to: Battery Tray - 1.6L EcoBoost (132kW/180PS) – Sigma (414-01 Battery, Mounting and Cables, Removal and Installation).

Refer to: Battery Tray - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma

(414-01 Battery, Mounting and Cables, Removal and Installation).

-

Remove the nuts and position the battery tray bracket aside.

-

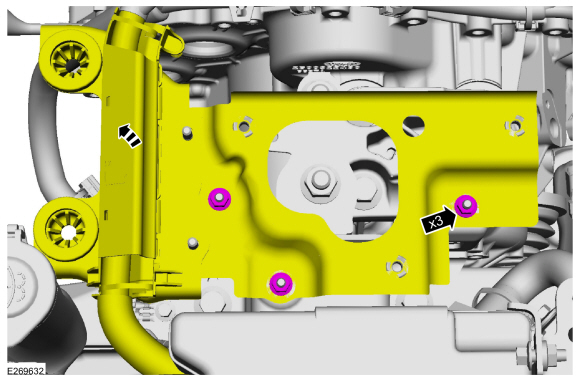

Tighten the roll restrictor bolts.

Torque:

52 lb.ft (70 Nm)

-

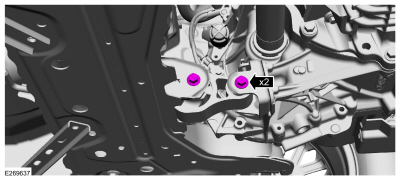

Tighten the transmission mounting assembly nuts.

Torque:

92 lb.ft (125 Nm)

-

Install the battery tray bracket and nuts.

Torque:

18 lb.ft (25 Nm)

-

Install the transmission cable and nut.

Torque:

89 lb.in (10 Nm)

-

Install the battery tray.

Refer to: Battery Tray - 1.6L EcoBoost (132kW/180PS) – Sigma (414-01 Battery, Mounting and Cables, Removal and Installation).

Refer to: Battery Tray - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma

(414-01 Battery, Mounting and Cables, Removal and Installation).

-

Install the battery.

Refer to: Battery (414-01 Battery, Mounting and Cables, Removal and Installation).

-

Position back the degas bottle.

-

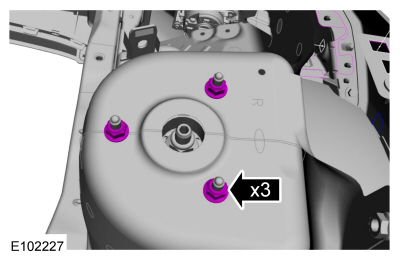

Tighten the engine mount bolts.

Torque:

35 lb.ft (48 Nm)

-

Test the system for normal operation.

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

Measure the diameter of each intake and exhaust valve

stem at the points shown...

Special Tool(s) /

General Equipment

Plastic Scraper

Nylon Bristle Disk

Plastic Razor Blade

Lint-Free Towel

Isopropyl Alcohol – 90 Percent Minimum

Materials

Name

Specification

Motorcraft® Silicone Gasket RemoverZC-30-A, AZC-30-C

-

Motorcraft® Metal Surface Prep WipesZC-31-B

-

Motorcraft® Engin..

Other information:

Removal

Remove the transmission.

Refer to: Transmission (308-03B Manual Transmission - 6-Speed Manual Transmission – B6, Removal).

Remove the bolts and the clutch slave cylinder.

Torque:

89 lb.in (10 Nm)

Installation

To install, reverse the removal procedure.

Bleed the air from the ..

Overview

The manual transmission external controls consists of the following:

Gearshift Cables

shift cable

selector cable

Gearshift lever

Gearshift lever knob and boot

Transmission shift lever

Transmission selector lever

System Operation

The

manual transmission is controlled by a floor-mounted gearshift lever..

Valve Stem Diameter. General Procedures

Valve Stem Diameter. General Procedures RTV Sealing Surface Cleaning and Preparation. General Procedures

RTV Sealing Surface Cleaning and Preparation. General Procedures Remove the strut and spring assembly upper mount nuts.

Remove the strut and spring assembly upper mount nuts.