Ford Fiesta: Engine System - General Information / Engine. Diagnosis and Testing

Inspection and Verification - Engine Performance

NOTE: There are 2 diagnostic paths that can be followed depending on the type of engine concern. Carry out Inspection and Verification - Engine Performance or Inspection and Verification - NVH .

NOTE: Some engines and transmissions are equipped with PTLP (powertrain limiting and protection) strategy that will limit power under various conditions to protect the engine and the transmission.

-

Verify the customer concern.

-

Visually inspect for obvious signs of mechanical or electrical damage.

-

If an obvious cause for an observed or reported concern is

found, correct the cause (if possible) before proceeding to the next

step.

-

NOTE: Make sure to use the latest scan tool software release.

If the cause is not visually evident, connect the scan tool to the DLC .

-

NOTE: The VCM LED prove out confirms power and ground from the DLC are provided to the VCM .

If the scan tool does not communicate with the VCM :

-

check the VCM connection to the vehicle.

-

check scan tool connection to the VCM .

-

check for No Power To The Scan Tool, to diagnose no power to the scan tool.

REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing).

-

check the VCM connection to the vehicle.

-

If the scan tool does not communicate with the vehicle:

-

verify the ignition key is in the ON position.

-

verify the scan tool operation with a known good vehicle.

-

to diagnose no response from the PCM ,

REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing).

-

verify the ignition key is in the ON position.

-

Carry out the network test.

-

If the scan tool responds with no communication for one or more modules,

REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing).

-

If the network test passes, retrieve and record continuous memory DTCs.

-

If the scan tool responds with no communication for one or more modules,

-

Clear the continuous DTCs and carry out the self-test diagnostics for the PCM .

-

If the DTCs retrieved are related to the concern, go to the DTC Chart.

REFER to: Electronic Engine Controls (303-14A Electronic Engine Controls - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma, Diagnosis and Testing).

or REFER to: Electronic Engine Controls (303-14B Electronic Engine Controls - 1.6L EcoBoost (132kW/180PS) – Sigma, Diagnosis and Testing).

or

-

If no DTCs related to the concern are retrieved, GO to Symptom Chart - Engine Performance.

Inspection and Verification - NVH

-

NVH

symptoms should be identified using the diagnostic tools and techniques

that are available. For a list of these techniques, tools, an

explanation of their uses and a glossary of common terms,

REFER to: Noise, Vibration and Harshness (NVH) (100-04 Noise, Vibration and Harshness, Diagnosis and Testing).

Since it is possible that any one of multiple systems may be the cause of the symptom, it may be necessary to use a process of elimination type of diagnostic approach to pinpoint the responsible system.

-

Verify the customer concern by operating the engine to duplicate the condition.

-

Check the engine oil level and check the oil for

contamination. Low engine oil level or contaminated oil are a common

cause of engine noise. If the oil is contaminated, the source of the

contamination must be identified and repaired as necessary.

-

Visually inspect for obvious signs of mechanical damage.

-

If the inspection reveals obvious concerns that can be readily identified, repair as necessary.

-

NOTE: Make sure to use the latest scan tool software release.

If the cause is not visually evident, connect the scan tool to the DLC .

-

NOTE: The VCM LED prove out confirms power and ground from the DLC are provided to the VCM .

If the scan tool does not communicate with the VCM :

-

check the VCM connection to the vehicle.

-

check the scan tool connection to the VCM .

-

check for No Power To The Scan Tool, to diagnose no power to the scan tool.

REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing).

-

check the VCM connection to the vehicle.

-

If the scan tool does not communicate with the vehicle:

-

verify the ignition key is in the ON position.

-

verify the scan tool operation with a known good vehicle.

-

to diagnose no response from the PCM ,

REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing).

-

verify the ignition key is in the ON position.

-

Carry out the network test.

-

If the scan tool responds with no communication for one or more modules,

REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing).

-

If the network test passes, retrieve and record continuous memory DTCs.

-

If the scan tool responds with no communication for one or more modules,

-

Clear the continuous DTCs and carry out the self-test diagnostics for the PCM .

-

If the DTCs retrieved are related to the concern, go to the DTC Chart.

REFER to: Electronic Engine Controls (303-14A Electronic Engine Controls - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma, Diagnosis and Testing).

or REFER to: Electronic Engine Controls (303-14B Electronic Engine Controls - 1.6L EcoBoost (132kW/180PS) – Sigma, Diagnosis and Testing).

or

-

If no DTCs related to the concern are retrieved, continue

the inspection and verification if a noise concern is related to the

engine. For vibration concerns and noise concerns such as powertrain

mounts, air intake system and starter GO to Symptom Chart - NVH .

In some cases, a noise may be a normal characteristic of that engine type. In other cases the noise may require further investigation. Comparing the noise to a similar year/model vehicle equipped with the same engine will aid in determining if the noise is normal or abnormal.

Once a customer concern has been identified as an abnormal engine noise, it is critical to determine the location of the specific noise. Use the EngineEAR/ChassisEAR or stethoscope (the noise will always be louder closer to the noise source) to isolate the location of the noise to one of the following areas.

- Fuel injector(s)

- Upper end of engine

- Lower end of engine

- Front of engine

- Rear of engine

Fuel injector noise

A common source of an engine ticking noise can be related to the fuel injection pump Gasoline Turbocharged Direct Injection (GTDI) engine or fuel injector(s). This is normal engine noise that can be verified by listening to another vehicle. If the injector noise is excessive or irregular, use the EngineEAR/ChassisEAR or stethoscope to isolate the noise to a specific fuel injector.

Upper end engine noise

A common source of upper end engine noise (ticking, knocking or rattle) include the camshaft(s) and valve train. Upper end engine noise can be determined using the EngineEAR/ChassisEAR or stethoscope on the valve cover bolts. If the noise is loudest from the valve cover bolts, then the noise is upper end. The EngineEAR/ChassisEAR or stethoscope can be used to further isolate the noise to the specific cylinder bank and cylinder. Removal of the valve covers will be required to pinpoint the source of the noise.

Lower end engine noise

A common source of lower end engine noise (ticking or knocking) include the crankshaft, connecting rod(s) and bearings. Lower end noises can be determined by using the oil pan or lower cylinder block. If the noise is loudest from these areas, then the noise is lower end. If an engine noise is isolated to the lower end, some disassembly of the engine may be required to inspect for damage or wear.

Front of engine noise

A common source of noise from the front of the engine (squeal,

chirp, whine or hoot) is the FEAD components. To isolate FEAD noise,

carry out the Engine Accessory Test.

REFER to: Noise, Vibration and Harshness (NVH) (100-04 Noise, Vibration and Harshness, Diagnosis and Testing).

Some other noises from the front of the engine (ticking, tapping or rattle) may be internal to the engine. Use the EngineEAR/ChassisEAR or stethoscope on the engine front cover to determine if the noise is internal to the engine. Removal of the engine front cover may be necessary to inspect internal engine components.

Rear of engine noise

A common source of noise from the rear of the engine (knocking) is the flywheel/flexplate. Inspection of the flywheel/flexplate will be necessary.

Some engines have timing drive components at the rear of the engine and may be the source of noise (ticking, knocking or rattle). Use the EngineEAR/ChassisEAR or stethoscope on the rear of the engine if the noise is suspected to be internal to the engine. Some disassembly of the engine may be required to inspect for damage or wear.

Turbocharger noise (Gasoline Turbocharged Direct Injection (GTDI) engine)

A common source of noise is the turbocharger. Some whine or air rush noise is an acceptable condition.

-

After the noise is localized, note the characteristics of

the noise, including type of noise, frequency and conditions when the

noise occurs and GO to Symptom Chart - NVH .

DTC Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

for information about these practices.

PCM DTC Chart

| DTC | Description | Action |

|---|---|---|

| P06DA | Engine Oil Pressure Control Circuit Open | GO to Pinpoint Test A |

| P06DB | Engine Oil Pressure Control Circuit Low | GO to Pinpoint Test A |

| P06DC | Engine Oil Pressure Control Circuit High | GO to Pinpoint Test A |

| P06DD | Engine Oil Pressure Control Circuit Performance/Stuck Off | GO to Pinpoint Test A |

| All Other DTCs | — |

Symptom Chart - Engine Performance

Symptom Chart - Engine Performance| Symptom | Possible Sources | Action |

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Symptom Chart - NVH

Symptom Chart - NVH| Symptom | Possible Sources | Action |

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pinpoint Tests

P06DA, P06DB, P06DC, P06DD

Refer to Wiring Diagrams Cell 23 for schematic and connector information.

Normal Operation and Fault Conditions

For more information,

DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| P06DA | Engine Oil Pressure Control Circuit Open | Sets when the PCM detects a circuit failure, an open on the engine oil pressure control solenoid valve circuit. |

| P06DB | Engine Oil Pressure Control Circuit Low | Sets when the PCM detects a circuit failure, short to ground on the engine oil pressure control solenoid valve circuit. |

| P06DC | Engine Oil Pressure Control Circuit High | Sets when the PCM detects a circuit failure, short to voltage on the engine oil pressure control solenoid valve circuit. |

| P06DD | Engine Oil Pressure Control Circuit Performance/Stuck Off | Sets when the PCM detects the engine oil pressure control solenoid valve is stuck. |

Possible Sources

- Wiring, terminals or connectors

- Engine oil pressure control solenoid valve

- PCM

PINPOINT TEST A: P06DA, P06DB, P06DC, P06DD

| A1 CHECK THE SUPPLY VOLTAGE TO THE ENGINE OIL PRESSURE CONTROL SOLENOID VALVE | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| A2 CHECK THE ENGINE OIL PRESSURE CONTROL SOLENOID VALVE CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| A3 CHECK THE ENGINE OIL PRESSURE CONTROL SOLENOID VALVE CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| A4 CHECK THE ENGINE OIL PRESSURE CONTROL SOLENOID VALVE CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| A5 CHECK THE ENGINE OIL PRESSURE CONTROL SOLENOID VALVE OPERATION | ||||||||||

Does the engine oil pressure drop to a lower pressure?

|

||||||||||

| A6 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

Component Tests

The following component tests are used to diagnose engine concerns.

Engine Oil Leaks

NOTE: If an overnight drive is done, the fan air or road air blast can cause erroneous readings.

NOTE: When diagnosing engine oil leaks, the source and location of the leak must be positively identified prior to repair.

Prior to carrying out this procedure, clean the cylinder block, cylinder heads, valve covers, oil pan and flywheel/flexplate with a suitable solvent to remove all traces of oil.

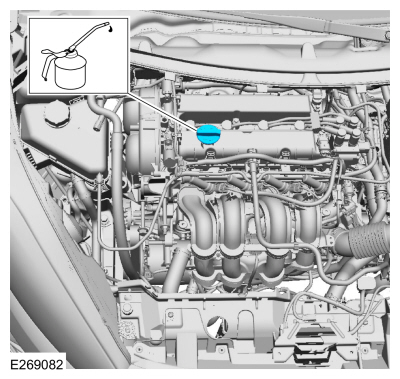

Engine Oil Leaks - Fluorescent Oil Additive Method

NOTE: If the factory fill engine oil with dye is present, change the engine oil and the oil filter prior to using the Dye-Lite® Oil-Based Fluid Dye (164-TP33200601).

Use the UV Long-Wave W/12-foot Cord & Alligator Clips (164-R3748) or Leak Tracker UV-LED Leak Detection Flashlight (164-TP8695) to carry out the following procedure for oil leak diagnosis.

-

Add 29.6 ml (1 fl oz) of Dye-Lite® Oil-Based Fluid Dye

(164-TP33200601) to a minimum of 0.47L (1/2 qt) and a maximum of 0.95L

(1 qt) engine oil. Thoroughly premix the oil based fluid dye or it will

not have enough time to reach the crankcase, oil galleries and seal

surfaces during this particular 15 minute test. The additive must be

added through the oil fill. Check the level on the oil level indicator

to determine what amount of oil to premix. If it is in the middle of the

crosshatch area or below the full mark, use 0.95L (1 qt). If it is at

the full mark, use 0.47L (1/2 qt).

-

NOTE: For best results allow the customer to drive the vehicle for a day.

Run the engine for 15 minutes. Stop the engine and inspect all seal and gasket areas for leaks using the UV Leak Detector Kit. A fluoresces white area will identify the leak. For extremely small leaks, several hours may be required for the leak to appear.

-

At the end of test, make sure the oil level is within

the upper and lower oil indicator marks. Remove oil as necessary if it

registers above the full mark.

Leakage Points - Underhood

Examine the following areas for oil leakage:

- Valve cover gaskets

- Cylinder head gaskets

- Oil cooler, if equipped

- Oil filter adapter

- Engine front cover

- Oil filter adapter and filter body

- Oil level indicator tube connection

- EOP switch

Leakage Points - Under Engine, With Vehicle on Hoist

Examine the following areas for oil leakage:

- Oil pan gaskets

- Oil pan sealer

- Engine front cover gasket

- Crankshaft front seal

- Crankshaft rear oil seal

- Oil filter adapter and filter body

- Oil cooler, if equipped

Leakage Points - With Transmission and Flywheel/Flexplate Removed

Examine the following areas for oil leakage:

- Crankshaft rear oil seal

- Rear main bearing cap parting line

- Flexplate mounting bolt holes (with flexplate installed)

- Pipe plugs at the end of oil passages

Compression Test

-

Make sure the oil in the crankcase is of the correct

viscosity and at the correct level and that the battery is correctly

charged. Operate the vehicle until the engine is at normal operating

temperature. Turn the ignition switch to the OFF position, then remove

all the spark plugs.

-

Set the throttle plates in the wide-open position.

-

Install a compression gauge in the No. 1 cylinder.

-

Install an auxiliary starter switch in the starting circuit.

With the ignition switch in the OFF position, and using the auxiliary

starter switch, crank the engine a minimum of 5 compression strokes and

record the highest reading. Note the approximate number of compression

strokes necessary to obtain the highest reading.

-

Repeat the test on each cylinder, cranking the engine approximately the same number of compression strokes.

Compression Test - Test Results

The indicated compression pressures are considered within specification if the lowest reading cylinder is at least 75% of the highest reading. Refer to the Compression Pressure Limit Chart.

Compression Pressure Limit Chart

NOTE: The indicated compression pressures are considered within specification if the lowest reading cylinder is at least 75% of the highest reading. Refer to the Compression Pressure Limit Chart.

| Maximum Cylinder Pressure - Minimal Cylinder Pressure | Maximum Cylinder Pressure - Minimal Cylinder Pressure | Maximum Cylinder Pressure - Minimal Cylinder Pressure | Maximum Cylinder Pressure - Minimal Cylinder Pressure |

| 134.0 –100.9 psi ( 924 –696 kPa) | 164.0 –123.0 psi ( 1,131 –848 kPa) | 194.1 –145.0 psi ( 1,338 –1,000 kPa) | 223.9 –168.0 psi ( 1,544 –1,158 kPa) |

| 136.0 –102.0 psi ( 938 –703 kPa) | 166.1 –124.0 psi ( 1,145 –855 kPa) | 195.9 –147.1 psi ( 1,351 –1,014 kPa) | 226.0 –169.0 psi ( 1,558 –1,165 kPa) |

| 138.1 –104.0 psi ( 952 –717 kPa) | 168.0 –126.0 psi ( 1,158 –869 kPa) | 198.0 –147.9 psi ( 1,365 –1,020 kPa) | 228.0 –171.0 psi ( 1,572 –1,179 kPa) |

| 140.0 –105.0 psi ( 965 –724 kPa) | 170.0 –127.1 psi ( 1,172 –876 kPa) | 200.0 –150.0 psi ( 1,379 –1,034 kPa) | 230.0 –172.0 psi ( 1,586 –1,186 kPa) |

| 142.0 –107.0 psi ( 979 –738 kPa) | 172.0 –128.9 psi ( 1,186 –889 kPa) | 201.9 –151.0 psi ( 1,392 –1,041 kPa) | 232.1 –174.0 psi ( 1,600 –1,200 kPa) |

| 143.9 –108.1 psi ( 992 –745 kPa) | 174.0 –131.0 psi ( 1,200 –903 kPa) | 204.1 –153.0 psi ( 1,407 –1,055 kPa) | 233.9 –175.1 psi ( 1,613 –1,207 kPa) |

| 146.1 –109.9 psi ( 1,007 –758 kPa) | 176.1 –132.0 psi ( 1,214 –910 kPa) | 206.0 –154.0 psi ( 1,420 –1,062 kPa) | 236.0 –176.9 psi ( 1,627 –1,220 kPa) |

| 147.9 –111.0 psi ( 1,020 –765 kPa) | 178.0 –133.0 psi ( 1,227 –917 kPa) | 208.0 –155.9 psi ( 1,434 –1,075 kPa) | 238.0 –178.0 psi ( 1,641 –1,227 kPa) |

| 150.0 –113.0 psi ( 1,034 –779 kPa) | 180.0 –135.0 psi ( 1,241 –931 kPa) | 210.0 –157.1 psi ( 1,448 –1,083 kPa) | 240.0 –180.0 psi ( 1,655 –1,241 kPa) |

| 152.0 –114.0 psi ( 1,048 –786 kPa) | 182.0 –135.8 psi ( 1,255 –936 kPa) | 212.0 –157.9 psi ( 1,462 –1,089 kPa) | 242.1 –181.0 psi ( 1,669 –1,248 kPa) |

| 154.0 –115.0 psi ( 1,062 –793 kPa) | 184.1 –138.1 psi ( 1,269 –952 kPa) | 214.1 –160.0 psi ( 1,476 –1,103 kPa) | 244.0 –183.0 psi ( 1,682 –1,262 kPa) |

| 156.1 –117.0 psi ( 1,076 –807 kPa) | 185.9 –140.0 psi ( 1,282 –965 kPa) | 216.0 –162.0 psi ( 1,489 –1,117 kPa) | 246.0 –184.1 psi ( 1,696 –1,269 kPa) |

| 157.9 –118.1 psi ( 1,089 –814 kPa) | 188.0 –141.0 psi ( 1,296 –972 kPa) | 218.0 –163.0 psi ( 1,503 –1,124 kPa) | 248.0 –174.3 psi ( 1,710 –1,202 kPa) |

| 160.0 –119.9 psi ( 1,103 –827 kPa) | 190.0 –142.0 psi ( 1,310 –979 kPa) | 220.0 –165.1 psi ( 1,517 –1,138 kPa) | 250.0 –187.0 psi ( 1,724 –1,289 kPa) |

| 161.0 –121.0 psi ( 1,110 –834 kPa) | 192.0 –144.0 psi ( 1,324 –993 kPa) | 236.6 –166.1 psi ( 1,631 –1,145 kPa) | 251.9 –189.0 psi ( 1,737 –1,303 kPa) |

If one or more cylinders reads low, squirt approximately one tablespoon of engine oil meeting Ford specification on top of the pistons in the low-reading cylinders. Repeat the compression pressure check on these cylinders.

Compression Test - Interpreting Compression Readings

-

If compression improves considerably, piston rings are worn or damaged.

-

If compression does not improve, valves are sticking or not seating correctly.

-

If 2 adjacent cylinders indicate low compression

pressures and squirting oil on each piston does not increase

compression, the head gasket may be leaking between cylinders. Engine

oil or coolant in cylinders could result from this condition. Use the

Compression Pressure Limit Chart when checking cylinder compression so

the lowest reading is within 75% of the highest reading.

Cylinder Leakage Detection

When a cylinder produces a low reading, use of a cylinder leakage tester will be helpful in pinpointing the exact cause.

The leakage tester is inserted in the spark plug hole, the piston is brought up to TDC on the compression stroke, and compressed air is admitted.

Once the combustion chamber is pressurized, the leakage tester gauge will read the percentage of leakage. Leakage exceeding 20% is excessive.

While the air pressure is retained in the cylinder, listen for the hiss of escaping air. A leak at the intake valve will be heard in the Throttle Body (TB). A leak at the exhaust valve can be heard at the tailpipe. Leakage past the piston rings will be audible at the PCV connection. If air is passing through a blown head gasket to an adjacent cylinder, the noise will be evident at the spark plug hole of the cylinder into which the air is leaking. Cracks in the cylinder block or gasket leakage into the cooling system may be detected by a stream of bubbles in the radiator.

Excessive Engine Oil Consumption

Nearly all engines consume oil, which is essential for normal lubrication of the cylinder bore walls and pistons and rings. Determining the level of oil consumption may require testing by recording how much oil is being added over a given set of miles.

Customer driving habits greatly influence oil consumption. Mileage accumulated during towing or heavy loading generates extra heat. Frequent short trips, stop-and-go type traffic or extensive idling, prevent the engine from reaching normal operating temperature. This prevents component clearances from reaching specified operating ranges.

The following diagnostic procedure may be utilized to determine internal oil consumption. Make sure that the concern is related to internal oil consumption, and not external leakage, which also consumes oil. Verify there are no leaks before carrying out the test. Once verified, the rate of internal oil consumption can be tested.

A new engine may require extra oil in the early stages of operation. Internal piston-to-bore clearances and sealing characteristics improve as the engine breaks in. Engines are designed for close tolerances and do not require break-in oils or additives. Use the oil specified in the Owner's Literature. Ambient temperatures may determine the oil viscosity specification. Verify that the correct oil is being used for the vehicle in the geographic region in which it is driven.

Basic Pre-checks

-

For persistent complaints of oil consumption, interview

the customer to determine the oil consumption characteristics. If

possible, determine the brand and grade of oil currently in the oil pan.

Look at the oil filter or oil-change station tags to determine if

Ford-recommended maintenance schedules have been followed. Make sure

that the oil has been changed at the specified mileage intervals. If

vehicle mileage is past the first recommended drain interval, the

Original Equipment Manufacturer (OEM) production filter should have been

changed.

-

Ask how the most current mileage was accumulated. That

is, determine whether the vehicle was driven under the following

conditions:

-

Extended idling or curbside engine operation

-

Stop-and-go traffic or taxi operation

-

Towing a trailer or vehicle loaded heavily

-

Frequent short trips (engine not up to normal operating temperature)

-

Excessive throttling or high engine-rpm driving

-

Extended idling or curbside engine operation

-

Verify that there are no external leaks. If necessary,

review the diagnostic procedure under Engine Oil Leaks in the Diagnosis

and Testing portion of this section.

-

Inspect the crankcase ventilation system for:

-

disconnected hoses at the valve cover or TB.

-

loose or missing valve cover fill cap.

-

missing or incorrectly seated engine oil level indicator.

-

incorrect or dirty PCV valve.

-

a PCV valve grommet unseated in the valve cover (if so equipped).

-

disconnected hoses at the valve cover or TB.

-

Inspect for signs of sludge. Sludge affects PCV

performance and can plug or restrict cylinder head drainback wells. It

can also increase oil pressure by restricting passages and reducing the

drainback capability of piston oil control rings. Sludge can result

from either excessive water ingestion in the crankcase or operation at

extremely high crankcase temperatures.

-

Inspect the air filter for dirt, sludge or damage. A

hole in the filter element will allow unfiltered air to bypass into the

air induction system. This can cause premature internal wear (engine

dusting), allowing oil to escape past rings, pistons, valves and guides.

-

If the engine is hot or was recently shut down, wait for

a minimum 10-minutes to allow the oil to drain back. Ask the customer

if this requirement has been followed. Adding oil without this wait

period can cause an overfill condition, leading to excessive oil

consumption and foaming which may cause engine damage.

-

Make sure the oil level indicator (dipstick) is

correctly and fully seated in the indicator tube. Remove the oil level

indicator and record the oil level.

Detailed Pre-checks

-

Check the thermostat opening temperature to make sure

that the cooling system is operating at the specified temperature. If it

is low, internal engine parts are not running at specified internal

operating clearances.

-

Verify the spark plugs are not oil saturated. Oil

leaking into one or more cylinders will appear as an oil soaked

condition on the plug. If a plug is saturated, a compression check may

be necessary at the conclusion of the oil consumption test.

Oil Consumption Test

-

NOTE: Once all of the previous conditions are met, carry out an oil consumption test.

Drain the engine oil and remove the oil filter. Install a new manufacturer-specified oil filter. Make sure the vehicle is positioned on a level surface. Refill the oil pan to a level one liter (quart) less than the specified fill level, using manufacturer-specified oil.

-

Run the engine for 3 minutes (if hot) or 10 minutes (if

cold). Allow for a minimum 10-minute drainback period and then record

the oil level shown on the oil level indicator. Place a mark on the

backside of the oil level indicator noting the oil level location.

-

Add the final one liter (quart) to complete the normal

oil fill. Restart the engine and allow it to idle for 2 minutes. Shut

the engine down.

-

After a minimum 10-minute drainback period, record the

location of the oil level again. Mark the oil level indicator with the

new oil level location. (Note: Both marks should be very close to the

MIN-MAX upper and lower limits or the upper and lower holes on the oil

level indicator. These marks will exactly measure the engine's use of

oil, with a one quart differential between the new marks.) Demonstrate

to the customer that the factory-calibrated marks on the oil level

indicator are where the oil should fall after an oil change with the

specified fill amount. Explain however, that this may vary slightly

between MIN-MAX or the upper and lower holes on the oil level indicator.

-

Record the vehicle mileage.

-

Advise the customer that oil level indicator readings

must be taken every 320 km (200 mi) or weekly, using the revised marks

as drawn. Remind the customer that the engine needs a minimum 10-minute

drainback period for an accurate reading and that the oil level

indicator must be firmly seated in the tube prior to taking the reading.

-

When the subsequent indicator readings demonstrate a

full liter (quart) has been used, record the vehicle mileage. The

mileage driven should not be less than 4,800 km (3,000 mi). The drive

cycle the vehicle has been operated under must be considered when making

this calculation. It may be necessary to have the customer bring the

vehicle in for a periodic oil level indicator reading to closely monitor

oil usage.

Post Checks, Evaluation and Corrective Action

-

If test results indicate excessive oil consumption,

carry out a cylinder compression test. The cylinder compression test

should be carried out with a fully charged battery and all spark plugs

removed. See the Compression Test Chart in this section for pressure

range limits.

-

Compression should be consistent across all cylinders.

Refer to the Compression Testing portion of this section. If compression

tested within the specifications found in this section, the excessive

oil consumption may be due to wear on the valve guides, valves or valve

seals.

-

A cylinder leak detection test can be carried out using a

cylinder leakage detector. This can help identify valves, piston rings,

or worn valve guides/valve stems, inoperative valve stem seals or other

related areas as the source of oil consumption.

-

NOTE: An oil-soaked appearance on the porcelain tips of the spark plugs also indicates excessive oil use. A typical engine with normal oil consumption will exhibit a light tan to brown appearance. A single or adjoining, multiple cylinder leak can be traced by viewing the tips.

If an internal engine part is isolated as the root cause, determine if the repair will exceed cost limits and proceed with a repair strategy as required.

-

Once corrective action to engine is complete and

verifying that all pre-check items were eliminated in the original

diagnosis, repeat the Oil Consumption Test as described above and verify

consumption results.

Intake Manifold Vacuum Test

Bring the engine to normal operating temperature. Connect the Vacuum/Pressure Tester to the intake manifold. Run the engine at the specified idle speed.

The vacuum gauge should read between 51-74 kPa (15-22 in-Hg) depending upon the engine condition and the altitude at which the test is conducted. Subtract 4.0193 kPa (1 in-Hg) from the specified reading for every 304.8 m (1,000 feet) of elevation above sea level.

The reading should be steady. If necessary, adjust the gauge damper control (where used) if the needle is fluttering rapidly. Adjust the damper until the needle moves easily without excessive flutter.

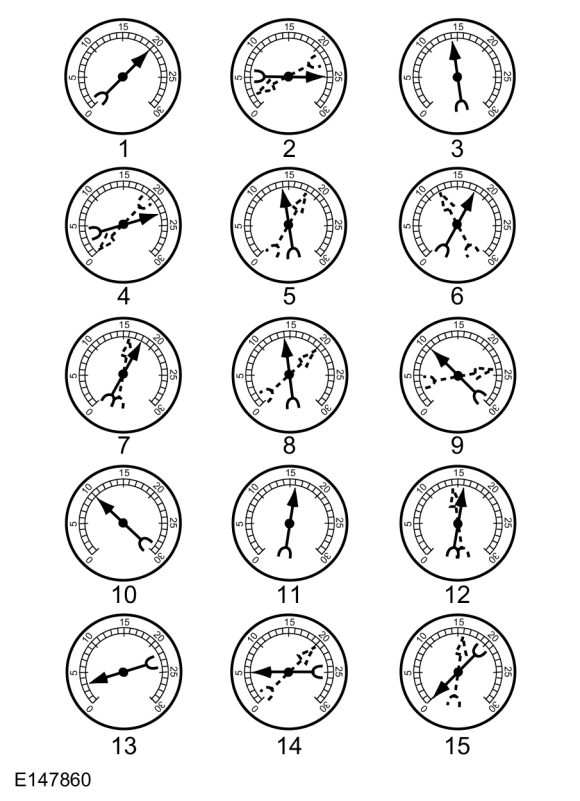

Intake Manifold Vacuum Test - Interpreting Vacuum Gauge Readings

A careful study of the vacuum gauge reading while the engine is idling will help pinpoint trouble areas. Always conduct other appropriate tests before arriving at a final diagnostic decision. Vacuum gauge readings, although helpful, must be interpreted carefully.

Most vacuum gauges have a normal band indicated on the gauge face. The following are potential gauge readings. Some are normal; others should be investigated further.

The following are potential gauge readings. Some are normal; others should be investigated further.

-

NORMAL READING: Needle between 51-74 kPa (15-22 in-Hg) and holding steady.

-

NORMAL READING DURING RAPID ACCELERATION AND

DECELERATION: When the engine is rapidly accelerated (dotted needle),

the needle will drop to a low reading (not to zero). When the throttle

is suddenly released, the needle will snap back up to a higher than

normal figure.

-

NORMAL FOR HIGH-LIFT CAMSHAFT WITH LARGE OVERLAP: The

needle will register as low as 51 kPa (15 in-Hg) but will be relatively

steady. Some oscillation is normal.

-

WORN RINGS OR DILUTED OIL: When the engine is

accelerated (dotted needle), the needle drops to 0 kPa (0 in-Hg). Upon

deceleration, the needle runs slightly above 74 kPa (22 in-Hg).

-

STICKING VALVES: When the needle (dotted) remains steady

at a normal vacuum but occasionally flicks (sharp, fast movement) down

and back about 13 kPa (4 in-Hg), one or more valves may be sticking.

-

BURNED OR WARPED VALVES: A regular, evenly-spaced,

downscale flicking of the needle indicates one or more burned or warped

valves. Insufficient valve clearance will also cause this reaction.

-

POOR VALVE SEATING: A small but regular downscale flicking can mean one or more valves are not seating.

-

WORN VALVE GUIDES: When the needle oscillates over about

a 13 kPa (4 in-Hg) range at idle speed, the valve guides could be worn.

As engine speed increases, the needle will become steady if guides are

responsible.

-

WEAK VALVE SPRINGS: When the needle oscillation becomes

more violent as engine rpm is increased, weak valve springs are

indicated. The reading at idle could be relatively steady.

-

LATE VALVE TIMING: A steady but low reading could be caused by late valve timing.

-

IGNITION TIMING RETARDING: Retarded ignition timing will produce a steady but somewhat low reading.

-

INSUFFICIENT SPARK PLUG GAP: When spark plugs are gapped

too close, a regular, small pulsation of the needle can occur.

-

INTAKE LEAK: A low, steady reading can be caused by an intake manifold or Throttle Body (TB) gasket leak.

-

BLOWN HEAD GASKET: A regular drop of fair magnitude can

be caused by a blown head gasket or warped cylinder head-to-cylinder

block surface.

-

RESTRICTED EXHAUST SYSTEM: When the engine is first

started and is idled, the reading may be normal, but as the engine rpm

is increased, the back pressure caused by a clogged muffler, kinked

tailpipe or other concerns will cause the needle to slowly drop to 0 kPa

(0 in-Hg). The needle then may slowly rise. Excessive exhaust clogging

will cause the needle to drop to a low point even if the engine is only

idling.

When vacuum leaks are indicated, search out and correct the cause. Excess air leaking into the system will upset the fuel mixture and cause concerns such as rough idle, missing on acceleration or burned valves. If the leak exists in an accessory unit such as the power brake booster, the unit will not function correctly. Always fix vacuum leaks.

Oil Pressure Test 1.0L Fox & 1.6L TIVCT

-

Disconnect and remove the EOP switch from the engine.

-

Connect the EOP Gauge to the oil pressure sender oil galley port.

-

Run the engine until normal operating temperature is reached.

-

Run the engine at the specified rpm and record the gauge reading.

-

The oil pressure should be within specifications, refer to

the specification chart in the appropriate 303-01 engine section.

-

If the pressure is not within specification, check the following possible sources:

-

Insufficient oil

-

Oil leakage

-

Worn or damaged oil pump

-

Oil pump screen cover and tube

-

Excessive main bearing clearance

-

Excessive connecting rod bearing clearance

-

Chain tensioner leak

-

Insufficient oil

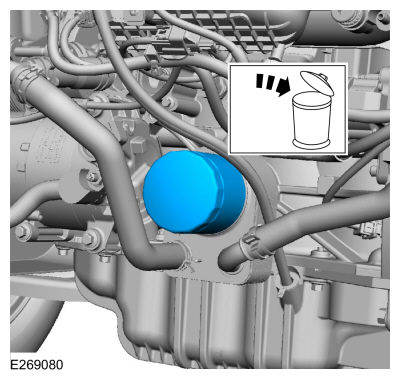

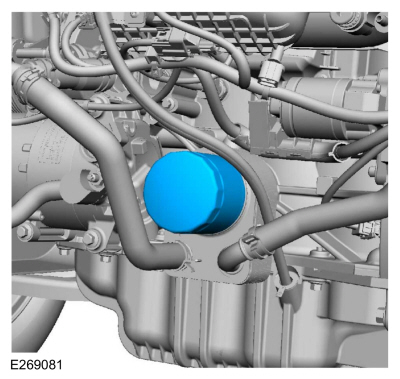

Oil Pressure Test 1.6L GTDI

-

With the vehicle in NEUTRAL, position it on a hoist.

REFER to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

Remove and discard the oil filter.

-

Connect a GearWrench 3289 Oil Pressure Tester Kit or equivalent oil pressure gauge to the oil filter housing.

-

Run the engine until normal operating temperature is reached.

-

Run the engine at the specified rpm and record the gauge reading.

-

The oil pressure should be within specifications, refer to

the specification chart in the appropriate 303-01 engine section.

-

If the pressure is not within specification, check the following possible sources:

-

Insufficient oil

-

Oil leakage

-

Worn or damaged oil pump

-

Oil pump screen cover and tube

-

Excessive main bearing clearance

-

Excessive connecting rod bearing clearance

-

Chain tensioner leak

-

Insufficient oil

-

Remove the commercially available oil pressure gauge.

-

Install a new manufacturer-specified oil filter.

-

Check and refill the oil as needed, using new manufacturer-specified oil.

Valve Train Analysis

The following component tests are used to diagnose valve train concerns.

Valve Train Analysis - Engine Off, Valve Cover Removed

Check for damaged or severely worn parts and correct assembly. Make sure correct parts are used with the static engine analysis as follows.

Valve Train Analysis - Camshafts and Valve Tappets

- Check for broken or damaged parts.

- Check for loose mounting bolts on camshaft caps.

- Check for worn or damaged valve tappets.

Valve Train Analysis - Valve Springs, Valve Tappets Removed

- Check for broken or damaged parts.

Valve Train Analysis - Valve Spring Retainer and Valve Spring Retainer Keys, Valve Tappets Removed

- Check for correct seating of the valve spring retainer key on the valve stem and in valve spring retainer.

- Check for correct seating on the valve stem.

Valve Train Analysis - Valves and Cylinder Head, Valve Tappets Removed

- Check for plugged oil drain back holes.

- Check for worn or damaged valve tips.

- Check for missing or damaged valve stem seals or guide-mounted valve stem seal.

- Check for missing or worn valve spring seats.

Valve Train Analysis - Camshaft Lobe Lift

Check the lift of each camshaft lobe in consecutive order and make a note of the readings.

-

Remove the spark plugs.

REFER to: Spark Plugs (303-07A Engine Ignition - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma, Removal and Installation).

REFER to: Spark Plugs (303-07B Engine Ignition - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

-

Install the Dial Indicator Gauge with Holding Fixture so

the rounded tip of the dial indicator is on top of the camshaft lobe

and on the same plane as the valve tappet.

-

Rotate the crankshaft using a breaker bar and socket

attached to the crankshaft pulley retainer bolt. Rotate the crankshaft

until the base circle of the camshaft lobe is reached.

-

Zero the dial indicator. Continue to rotate the

crankshaft until the high-lift point of the camshaft lobe is in the

fully raised position (highest indicator reading).

-

To check the accuracy of the original dial indicator

reading, continue to rotate crankshaft until the base circle is reached.

The indicator reading should be zero. If zero reading is not obtained,

repeat Steps 2 through 5.

-

If the lift on any lobe is below specified service limits, install a new camshaft and valve tappets.

-

Install the spark plugs.

REFER to: Spark Plugs (303-07A Engine Ignition - 1.6L Duratec-16V Ti-VCT (88kW/120PS) – Sigma, Removal and Installation).

REFER to: Spark Plugs (303-07B Engine Ignition - 1.6L EcoBoost (132kW/180PS) – Sigma, Removal and Installation).

Engine - Overview. Description and Operation

Engine - Overview. Description and Operation

Engine Information

NOTE:

When repairing engines, all parts must be contamination

free. If contamination/foreign material is present when repairing an

engine, premature engine failure may occur...

Bearing Inspection. General Procedures

Bearing Inspection. General Procedures

Inspection

Cratering - fatigue failure

Spot glazing - incorrect seating

Scratching - dirty engine oil

Base exposed - poor lubrication

Both edges worn - journal damaged

One edge worn - journal tapered or bearing not seated

..

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Microphone. Removal and Installation

Special Tool(s) / General Equipment Interior Trim Remover Removal NOTE: If the microphone is removed from the headliner, a new microphone must be installed. Headliner Microphone Pry the microphone bezel from the headliner metal mounting bracket and remove the microphone from the headliner by grasping the microphone pigtail. Dis..

Ford Fiesta 2014 - 2019 Service Manual: Brake Disc Shield. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the brake disc. Refer to: Brake Disc (206-03 Front Disc Brake, Removal and Installation). Remove the bolts and the brake disc shield. Torque: 80 lb.in (9 Nm) Installation To install, reverse the removal proce..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Front Strut and Spring Assembly. Removal and Installation

- Engine - 1.6L EcoBoost (132kW/180PS) – Sigma

- Engine System - General Information

- Maintenance Schedules

- Jacking and Lifting - Overview. Description and Operation

Axle. Removal and Installation

Special Tool(s) / General Equipment

Flat Headed Screw Driver Transmission Jack Vehicle/Axle StandsRemoval

NOTICE: Suspension fasteners are critical parts that affect performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

Remove the floor console.Refer to: Floor Console (501-12 Instrum