Ford Fiesta: Perimeter Anti-Theft Alarm / Perimeter Anti-Theft Alarm. Diagnosis and Testing

BCM DTC Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: About this Manual (100-00 General Information, Description and Operation).

| DTC | Description | Action |

|---|---|---|

| B10B1:92 | Cabin Set/Reset Switch: Performance or Incorrect Operation | GO to Pinpoint Test B |

| B112C:87 | Interior Motion Sensor: Missing Message | GO to Pinpoint Test F |

| B112C:96 | Interior Motion Sensor: Component Internal Failure | INSTALL a new intrusion sensor. |

| P254F:00 | Engine Hood Switch Circuit/Open: No Sub Type Information | GO to Pinpoint Test E |

| All other Diagnostic Trouble Codes (DTCs) | - |

REFER to: Body Control Module (BCM) (419-10 Multifunction Electronic Modules, Diagnosis and Testing). |

Symptom Chart

Symptom Chart: Anti-Theft - Perimeter

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: About this Manual (100-00 General Information, Description and Operation).

Symptom Chart

| Condition | Possible Causes | Actions |

|---|---|---|

| The alarm system does not activate from an unauthorized entry at the hood |

|

|

| The alarm system does not activate from an unauthorized entry at a door |

|

|

| The alarm system does not activate from an unauthorized entry at the liftgate/luggage compartment lid |

|

|

| The perimeter alarm does not arm/disarm from the driver door lock cylinder |

|

|

| The alarm system does not arm/no turn signals flash confirmation |

|

|

| No horn output during alarm activation (traffic horn) |

|

|

| No horn output during alarm activation (anti-theft alarm horn) |

|

|

| False alarm activation |

|

|

Pinpoint Tests

The Alarm System Does Not Activate from an Unauthorized Entry at the Hood

Refer to Wiring Diagrams Cell 117 for schematic and connector information.

Normal Operations and Fault Conditions

REFER to: Perimeter Anti-Theft Alarm - System Operation and

Component Description (419-01A Perimeter Anti-Theft Alarm, Description

and Operation).

Possible Causes

- Wiring, terminals or connectors

- Hood latch

- BCM

Visual Inspection and Diagnostic Pre-checks

- Inspect the hood latch for damage.

PINPOINT TEST A: THE ALARM SYSTEM DOES NOT ACTIVATE FROM AN UNAUTHORIZED ENTRY AT THE HOOD

| A1 MONITOR THE BCM (BODY CONTROL MODULE) HOOD AJAR SWITCH (HOOD_SW) PID (PARAMETER IDENTIFICATION) | ||||||||||

Does the PID read AJAR when the switch is disconnected?

|

||||||||||

| A2 CHECK THE HOOD AJAR SWITCH INPUT CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| A3 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

The Perimeter Alarm Does Not Arm/Disarm From The Driver Door Lock Cylinder

Refer to Wiring Diagrams Cell 117 for schematic and connector information.

Normal Operations and Fault Conditions

REFER to: Perimeter Anti-Theft Alarm - System Operation and

Component Description (419-01A Perimeter Anti-Theft Alarm, Description

and Operation).

BCM DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| B10B1:92 | Cabin Set/Reset Switch: Performance or Incorrect Operation | Sets when the BCM detects a short to ground from one of the driver door lock cylinder input circuits during a self-test. |

Possible Causes

- Arm/disarm switch (part of the driver door latch)

- Driver door key cylinder linkage

- Driver door latch

- BCM

PINPOINT TEST B: THE PERIMETER ALARM DOES NOT ARM/DISARM FROM THE DRIVER DOOR LOCK CYLINDER

| B1 RETRIEVE THE RECORDED DIAGNOSTIC TROUBLE CODES (DTCS) FROM THE BCM (BODY CONTROL MODULE) | ||||||||||||||||

Is DTC B10B1:92 present?

|

||||||||||||||||

| B2 CHECK THE DRIVER DOOR LATCH FOR AN INTERNAL SHORT TO GROUND | ||||||||||||||||

Is DTC B10B1:92 still present?

|

||||||||||||||||

| B3 CHECK THE DOOR LOCK CYLINDER SET/RESET CIRCUITS FOR A SHORT TO GROUND | ||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

||||||||||||||||

| B4 VERIFY THE COURTESY LAMP OPERATION | ||||||||||||||||

Do the courtesy lamps operate correctly?

|

||||||||||||||||

| B5 BYPASS THE DRIVER DOOR LATCH WHILE CHECKING THE DRIVER DOOR LOCK CYLINDER (KCS_DRVR) PID (PARAMETER IDENTIFICATION) | ||||||||||||||||

Does the PID indicate LOCK and UNLOCK when the jumper wire is connected?

|

||||||||||||||||

| B6 CHECK THE DOOR LOCK CYLINDER SET/RESET CIRCUITS FOR AN OPEN | ||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||

| B7 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||||||||

Is the concern still present?

|

The Alarm System Does Not Arm/No Turn Signals Flash Confirmation

Normal Operations and Fault Conditions

REFER to: Perimeter Anti-Theft Alarm - System Operation and

Component Description (419-01A Perimeter Anti-Theft Alarm, Description

and Operation).

Possible Causes

- Door ajar input

- Hood switch input

- Liftgate/luggage compartment lid ajar input

- Turn signal output

- RKE transmitter concern

- BCM

PINPOINT TEST C: THE ALARM SYSTEM DOES NOT ARM/NO TURN SIGNALS FLASH CONFIRMATION

| C1 RETRIEVE THE RECORDED DIAGNOSTIC TROUBLE CODES (DTCS) FROM THE BCM (BODY CONTROL MODULE) | ||||

|

NOTE: DTC P254F:00 sets if the hood is open. Make sure the hood is closed prior to running the self-test.

Is DTC P254F:00 present?

|

||||

| C2 CHECK THE DOOR AJAR SWITCH INPUT | ||||

Does the IPC indicate a door is ajar?

|

||||

| C3 MONITOR THE LIFTGATE/LUGGAGE COMPARTMENT LID AJAR SWITCH INPUT | ||||

Does the IPC indicate the liftgate/luggage compartment lid is ajar?

|

||||

| C4 VERIFY THE HAZARD FLASHER LAMP OPERATION | ||||

Do all the turn signals flash on and off?

|

||||

| C5 CHECK THE RKE (REMOTE KEYLESS ENTRY) TRANSMITTER FUNCTION | ||||

Do the doors lock and unlock?

|

||||

| C6 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||

Is the concern still present?

|

No Horn Output During Alarm Activation (Anti-Theft Alarm Horn)

Refer to Wiring Diagrams Cell 117 for schematic and connector information.

Normal Operations and Fault Conditions

REFER to: Perimeter Anti-Theft Alarm - System Operation and

Component Description (419-01A Perimeter Anti-Theft Alarm, Description

and Operation).

Possible Causes

- Wiring, terminals or connectors

- Anti-theft alarm horn

- BCM

PINPOINT TEST D: NO HORN OUTPUT DURING ALARM ACTIVATION (ANTI-THEFT ALARM HORN)

| D1 CHECK FOR VOLTAGE TO THE ANTI-THEFT ALARM HORN USING THE BCM (BODY CONTROL MODULE) ANTI-THEFT ALARM HORN (ANTITHFT_HRN) PID (PARAMETER IDENTIFICATION) | ||||||||||

|

NOTE: The following pinpoint test step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector.

Does the test lamp illuminate when the anti-theft horn is commanded on?

|

||||||||||

| D2 CHECK THE ANTI-THEFT ALARM HORN CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| D3 CHECK THE ANTI-THEFT ALARM HORN CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| D4 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

P254F:00

Refer to Wiring Diagrams Cell 117 for schematic and connector information.

Normal Operations and Fault Conditions

REFER to: Perimeter Anti-Theft Alarm - System Operation and

Component Description (419-01A Perimeter Anti-Theft Alarm, Description

and Operation).

BCM DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| P254F:00 | Hood Switch: General Electrical Failure | Sets when the BCM detects an open from the hood ajar switch input during the self-test. |

Possible Causes

- Wiring, terminals or connectors

- Hood latch

- BCM

Visual Inspection and Diagnostic Pre-checks

- Inspect the hood latch for damage.

PINPOINT TEST E: P254F:00

| E1 ISOLATE THE HOOD AJAR SWITCH | ||||||||||

Is DTC P254F:00 still present?

|

||||||||||

| E2 CHECK THE HOOD AJAR SWITCH GROUND CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| E3 CHECK THE HOOD AJAR SWITCH INPUT CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| E4 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

B112C:87

Refer to Wiring Diagrams Cell 112 for schematic and connector information.

Normal Operations and Fault Conditions

REFER to: Perimeter Anti-Theft Alarm - System Operation and

Component Description (419-01A Perimeter Anti-Theft Alarm, Description

and Operation).

BCM DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Conditions |

|---|---|---|

| B112C:87 | Interior Motion Sensor: Missing Message | Sets when the BCM loses communication with the intrusion sensor. |

Possible Causes

- Wiring, terminals or connectors

- Intrusion sensor

- BCM

PINPOINT TEST F: B112C:87

| F1 CHECK THE INTRUSION SENSOR VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the voltage greater than 10 volts?

|

||||||||||

| F2 CHECK THE INTRUSION SENSOR GROUND CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| F3 CHECK THE INTRUSION SENSOR LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| F4 CHECK THE INTRUSION SENSOR LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| F5 CHECK THE INTRUSION SENSOR LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| F6 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

Perimeter Anti-Theft Alarm - System Operation and Component Description. Description and Operation

Perimeter Anti-Theft Alarm - System Operation and Component Description. Description and Operation

S..

Other information:

Ford Fiesta 2014 - 2019 Service Manual: Pinpoint Test - DTC: S. Diagnosis and Testing

B1408:11, B1408:12, B1408:13 and B1408:1A Refer to Wiring Diagrams Cell 46 for schematic and connector information. Normal Operation and Fault Conditions The RCM continuously monitors the RH side air curtain circuits for the following faults: Resistance out of range Unexpected voltage Short to ground Faulted RH side air curtain If..

Ford Fiesta 2014 - 2019 Service Manual: Front Door Speaker. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the front door trim panel. Refer to: Front Door Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation). Remove the bolts and the speaker. Disconnect the electrical connector. Torque: 18 lb.in (2 Nm) ..

Categories

- Manuals Home

- Ford Fiesta Service Manual (2014 - 2019)

- Front Strut and Spring Assembly. Removal and Installation

- Front Suspension

- Manual Transmission - 6-Speed Manual Transmission – B6

- Valve Clearance Adjustment. General Procedures

- Maintenance Schedules - Gasoline Engines. Description and Operation

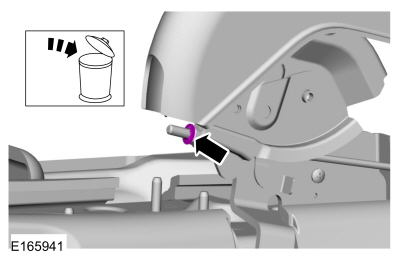

Parking Brake Control. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

Remove the floor console.Refer to: Floor Console (501-12 Instrument Panel and Console, Removal and Installation).

Remove the driver seat.

Refer to: Front Seat (501-10 Seating, Removal and Installation).

Remove the parking brake cable adjustment lock nut.

Loosen the parking brake cable adjustment nut.

Loosen the parking brake cable adjustment nut.